F-22 Raptor pilots are currently testing out a next-generation helmet for fixed-wing U.S. Air Force aircrew members. Dubbed the Next Generation Fixed Wing Helmet (NGFWH), the headgear is designed to better support advances in helmet-mounted display systems while providing a more comfortable wearing experience over the HGU-55/P first introduced in the 1980s that is presently worn by pilots.

The new helmet is being designed by the California-based company LIFT Airborne Technologies, which has officially designated the headgear as AV 2.2 NGFWH. Eglin Air Force Base in Florida is leading the most recent round of developmental testing for the helmet, with engineers from the 46th Test Squadron and the 28th Test and Evaluation Squadron overseeing the activities. According to an Air Force press release, five F-22A Raptor pilots from the 301st Fighter Squadron, which is a reserve unit with the 43rd Fighter Squadron at Eglin, will be carrying out flight tests wearing the NGFWH.

After each test, the Raptor pilots report back with any comments, questions, or concerns about the NGFWH that may have arisen throughout the flight. The engineers from both test squadrons then take that feedback and provide it to the manufacturer to further inform the helmet’s evolution. The Air Force noted in the press release that aside from some minor tweaks, pilot experience flying with the NGFWH has been largely positive.

“The design of the helmet allows for unparalleled visibility, mobility, and comfort in the cockpit,” said Maj. Brett Gedman, from the 301st Fighter Squadron. “The increased visibility combined with the mobility it provides made it a massive improvement over what I am used to flying with. It is clear this has been a generational leap in technology that the fighter pilot deserves, which is long overdue.”

LIFT was chosen to continue developing the helmet following a prototype competition launched by AFWERX in 2019. The Air Force stated that over 100 different designs were submitted in hopes of being selected to replace the dated HGU-55/P.

Key parameters set by the Air Force for participating companies included reduced weight, enhanced pilot comfort, optimized fitment and protection, increased stability, a more supported center of gravity, and the ability to integrate with different helmet-mounted systems. In 2022, the Air Force formally announced LIFT had won the NGFWH competition and would be continuing prototype development of its AV 2.2 helmet, which is now in its second phase of testing.

Perhaps the most significant driver behind equipping fixed-wing aircrew with new helmets, excluding F-35 Lightning II pilots who have their own headgear, has been the proliferation of high-tech helmet-mounted devices like cueing systems and night vision goggles. The Air Force has said that the legacy HGU-55/P wasn’t designed to accommodate advances in aircraft helmet-mounted display systems, which often means that the headgear’s center of gravity is altered as various new devices are bolted onto it.

The constant shift in weight distribution when using the HGU-55/P has contributed to widespread neck and back issues among Air Force fixed-wing pilots and can lead to even longer-term problems the more often the aviator is subjected to the discomfort. It’s also worth noting that while HGU-55/P weighs about 2.2 pounds, per data provided by its manufacturer Gentex, that load is only multiplied when a pilot pulls a high-G maneuver, especially as weight is extended out further its center via clip-on devices. Three pounds worth of headgear turns into an equivalent of 27 pounds when under a 9G load, for instance.

“It is common knowledge [that] fighter pilots have long-term neck and back issues,” said Maj. Brett Gedman, from the 301st Fighter Squadron. “Therefore, having a lightweight helmet, designed with the operator in mind, will have positive long-term impacts on the health of our fighter pilots during and after service.”

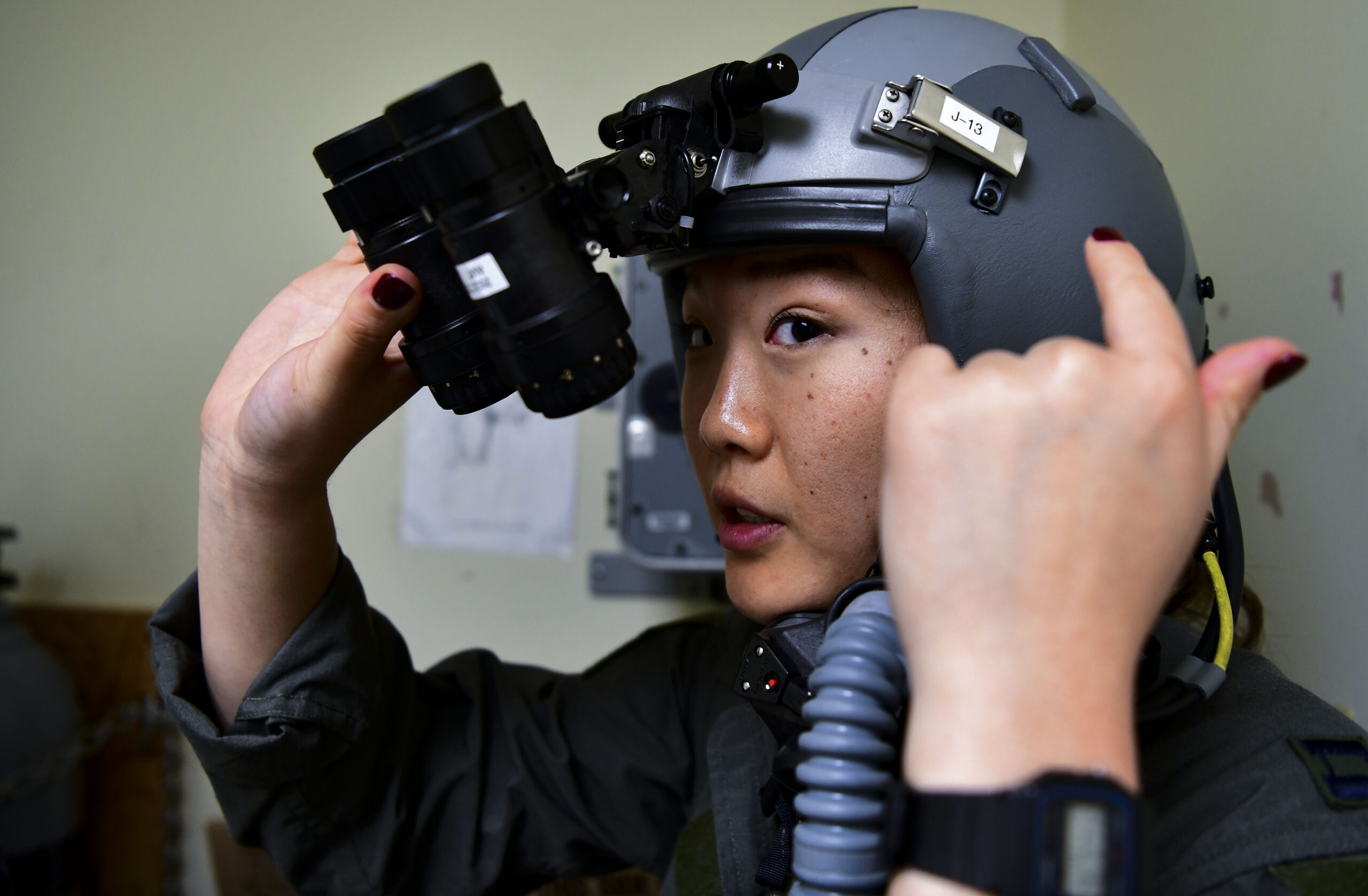

Poor ventilation, minimal options for adjustability, and a ‘one-size-fits-all’ design that prevented many female pilots and aviators of varying sizes from comfortably wearing the helmet have all been criticisms of the HGU-55/P throughout its service life, as well. Each drawback has been pulled together to inform the development of LIFT’s NGFWH.

For instance, LIFT states that NGFWH, which is made predominately of carbon fiber, is 42% lighter with head-worn weight compared to its competitors. The NGFWH is also engineered with vents at the back to increase airflow and comes with adjustable knobs intended specifically to customize the helmet to the desired fit. LIFT has additionally designed the helmet with padded liners that can be personalized using any combination of 7-, 10-, or 13-millimeter thicknesses.

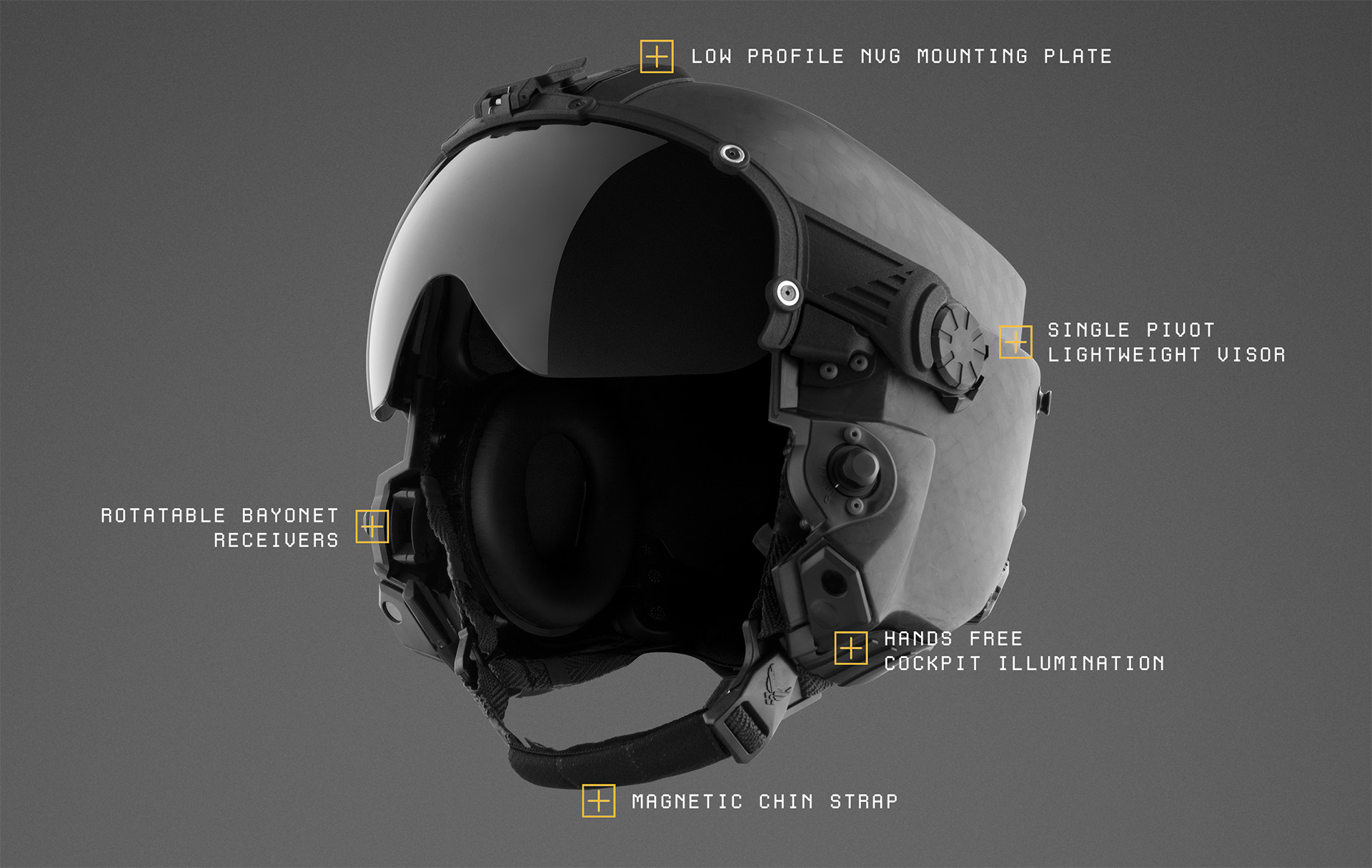

Making sure at least one of the pilot’s hands will be free when adjusting the helmet is an underlying theme of LIFT’s prototype. The company’s website details that the NGFWH comes with a top-actuated single-pivot dual visor assembly made of polycarbonate that allows the pilot to raise or lower the transparency single-handedly.

The new helmet also includes an adjustable magnetic chin strap that can withstand more than 438 pounds of force and can be mated to the helmet with just one hand. Along with that, a hands-free cockpit illumination capability designed into the helmet allows the pilot to toggle lights mounted to each side simply by clenching their jaw, as our friends at Task & Purpose highlighted in the past.

An internal pair of rotatable bayonet receivers will facilitate the attachment of oxygen masks to the helmet and offer up to 45 degrees of receiver adjustment per side. NGFWH also eliminates the need for a helmet-mounted battery as the company has implemented its Aircrew Mounted Power Supply, which is an off-helmet unit that further reduces the weight carried by the headgear.

LIFT is also touting the NGFWH’s standard-issue Active Noise Reduction capability, which is intended to improve speech intelligibility across a wide frequency spectrum as well as reduce the ever-present and loud engine noise when flying fixed-wing aircraft. It will be interesting to see if other advancements in cockpit audio are eventually used with NGFWH’s design, perhaps like the surround sound Aircraft Audio Management System (AAMS) designed by Terma for the A-10 Warthog ground attack aircraft.

The benefits NGFWH could provide would extend beyond pilots, as well. In its press release, the Air Force spoke to Aircrew Flight Equipment (AFE) technicians who lauded the ease with which they’re able to prepare and maintain the helmet for flight. With the HGU-55/P, AFEs were tasked with manually adding, adjusting, and fitting standard helmet-mounted devices like night-vision goggle mounts and an adjustable occipital basket to each individual pilot’s helmet, which can reportedly take hours and requires the use of various power tools.

“From a pre-flight and build-up standpoint, the new helmet is much better,” said Airman 1st Class Matthew Crouse, a 325th Operations Support Squadron AFE technician responsible for NGFWH maintenance at Eglin. “It makes our job much easier in the long run, but because it’s so easy to adjust, we can make corrections if they are needed.”

As for NGFWH’s development timeline, the Air Force stated that when the Raptor squadrons leave Eglin for Joint Base Langley-Eustis, Virginia in the near future, the test engineers will follow and continue evaluations with a new set of pilots. The HC-130J and B-1B Lancer are the next aircraft slated to begin flight testing with the new helmets. LIFT plans to begin producing the helmets in 2024 if testing goes well, and a phased approach will be taken in the delivery of NGFWH, beginning with the F-15E Strike Eagle.

Until then, the NGFWH is expected to be a welcomed improvement over the existing HGU-55/P helmets that have been a literal pain in the neck for fixed-wing pilots to wear over the last several years.

Contact the author: Emma@thewarzone.com