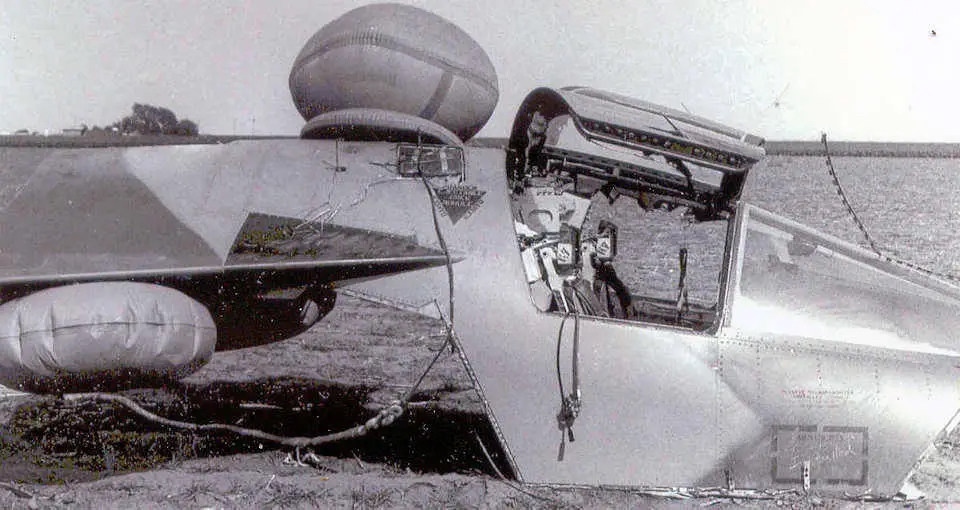

On March 30, 1968, Maj. Sandy Marquardt and Capt. Joe Hodges of the U.S. Air Force were forced to use the escape module of their swing-wing F-111 Aardvark strike jet. The F-111A, which had yet to clear U.S. Air Force acceptance trials, was sent on its first operational deployment to demonstrate its precision strike capabilities at low levels in northern Vietnam in mid-March, 1968. Marquardt and Hodges — who were forward deployed for these inaugural missions — survived the incident unscathed and, just a few weeks later, were reunited with the escape module responsible for saving their lives.

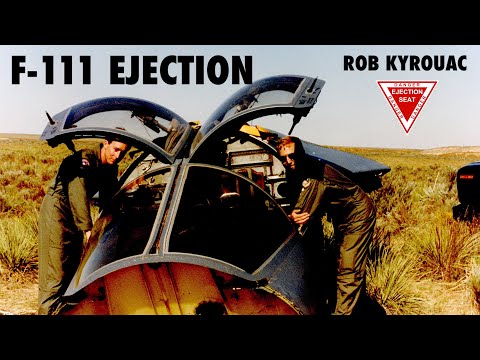

The cover image in this article of Marquardt and Hodges sitting in the escape module underscores two points. Most obviously, it illustrates how the Aardvark’s unusual ejection mechanism, while highly complex, proved early on to be a life-saving part of its design. Ejection involved virtually the whole cockpit and upper forward portion of the jet being severed from the aircraft. The ejection module was watertight and self-contained, allowing for landings at sea, and offered airmen protection when ejecting from the aircraft at very high speeds. It also shielded them from environmental hazards.

Yet the photo also alludes to the poor operational debut of the F-111A with the Air Force during the Vietnam War. Marquardt and Hodges’ F-111A — serial number 66-0017 — was not the only Aardvark to be lost during the aircraft’s initial deployment to Southeast Asia. Two others crashed in March and April of 1968. Technical as well as environmental factors played a part in these losses.

The Air Force had a more successful relationship with the jet in the following years, however. In total, the service accepted 562 F-111s, including 159 F-111As, 24 F-111Cs, 96 F-111Ds, 94 F-111Es, 106 F-111Fs, and 76 FB-111As, with the F-111 being used by the service until 1996. 42 EF-111A Ravens, an electronic warfare version of the F-111, were accepted by the Air Force between 1981-1985 and flew with the service until 1998. Seven pre-production naval F-111Bs were accepted for the Navy, although the variant never went into production, owing to the Navy’s shifting aircraft requirements in 1968 and the aircraft’s lackluster performance in the naval environment.

Before exploring why the Aardvark’s escape module was used so early in its operational career, we need to look back to the early-1960s when plans for the aircraft began to take shape.

When Robert McNamara was appointed Secretary of Defense in January 1961, he aimed to introduce a new tactical fighter jet that met the needs of both the Air Force and the Navy. At the time, the Air Force was looking for a Republic F-105 Thunderchief successor, while the Navy was seeking a McDonnell Douglas F-4 Phantom replacement.

As Peter Davies notes in his book, F-111 and EF-111 Units In Combat, both services were looking for an aircraft with similar characteristics, albeit for different mission sets. Both the Air Force and Navy wanted an aircraft that could carry greater fuel loads and heavy armament, be able to fly at high supersonic speeds, and have two engines and two crew members. The Air Force was specifically looking for a land-based, strike aircraft with the potential to travel at speeds of up to Mach 2.5.

The Tactical Fighter Experimental (TFX) competition for the new aircraft overseen by the Air Force was ultimately won by General Dynamics, besting Boeing for the final contract, which was signed in December 1962. In addition to General Dynamics as the main contractor, 17 additional sub-contractors were responsible for the aircraft’s subsystems. The F-111 subsequently made its first flight two years later in December 1964.

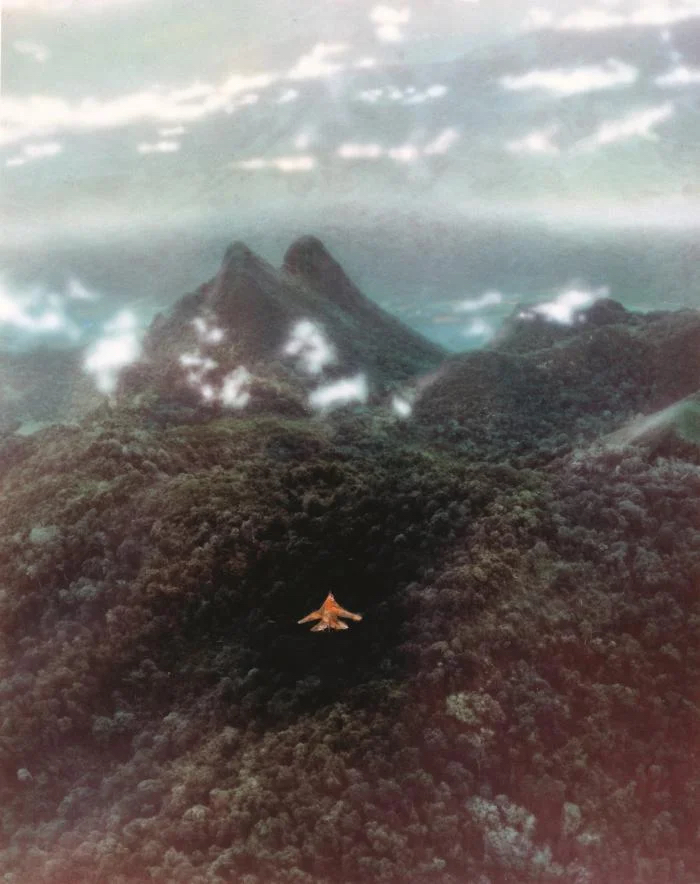

The first pre-production F-111s built in 1967 were earmarked for test, trials, and evaluation. 18 research, development, test and evaluation (RDT&E) aircraft were tested at Eglin Air Force Base in Florida and Edwards Air Force Base in California in the spring of 1967. Combat Bullseye I, as those tests were termed, demonstrated the superior bombing accuracy of the F-111’s cutting-edge attack radar. The aircraft also featured an automatic terrain-following radar (TFR) system. This enabled the aircraft to operate at a continuous altitude as low as 200 feet above uneven terrain at night and amid poor weather conditions. You can read what it was like flying with it, and the F-111 overall, in this past feature of ours.

A new method of ejecting airmen via a module, with greater levels of protection compared to standard seat ejections where pilots were exposed to the elements, came in response to the aircraft’s high speed capabilities. Its maximum speed — which clocked in at Mach 2.2, or 1,672 miles per hour (altitude dependent), with a service ceiling of 60,000 feet — was aided by its variable-geometry wings and inlet ‘spike and cone’ design, the latter of which you can read more about here. It helped feed massive volumes of stable air into the jet’s twin Pratt & Whitney TF30 turbofan engines — state-of-the-art in an era dominated by turbojets.

As the Air Force instructional video on the F-111 crew module escape system below highlights, even at speeds of 300 knots (345 miles per hour) the simulated projection of pilots ejecting from F-106 Delta Darts via traditional ejection seats was less than certain. The service needed an escape system that would stabilize pilots traveling at supersonic speeds, ensuring higher chances of survival.

After initiating ejection in the F-111 by pulling an ejection handle, an explosive train is triggered surrounding the module, the reel highlights. The pilots are automatically cinched back into their seats, and an emergency 10 minute oxygen supply begins operating. The bulk of heavy lines and cables connecting the cockpit module with the fuselage are severed by guillotines.

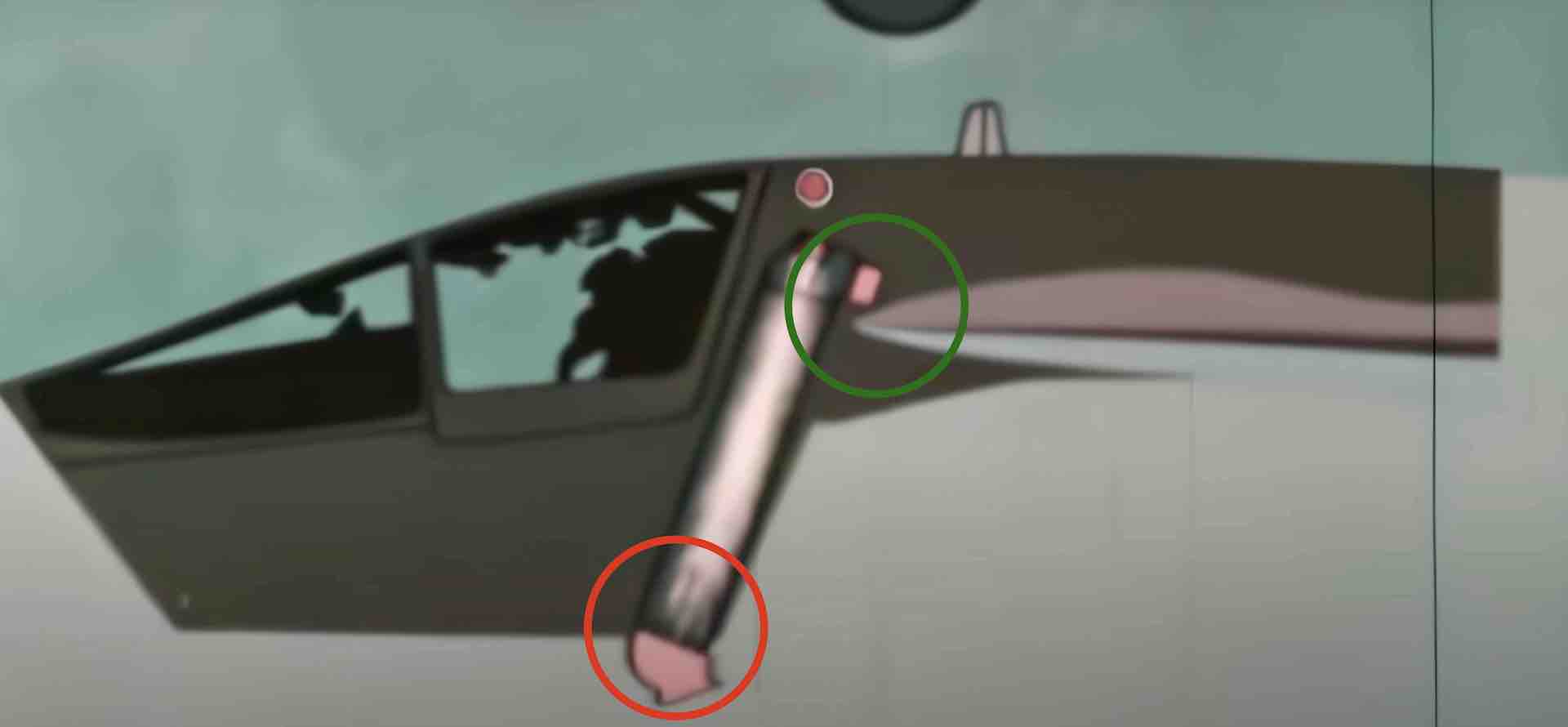

Following a short delay, a rocket motor is activated. A sensor, located at the top of the rocket determines the speed of the aircraft and the appropriate amount of force needed for clearing the fuselage and keeping the crew alive. A lower primary nozzle connected to the rocket delivers up to 27,000 pounds of thrust, while an auxiliary nozzle delivers up to 7,000 pounds. When traveling at speeds in excess of 345 miles per hour, both nozzles are used — the lower nozzle delivering 9,000 pounds of thrust, the auxiliary delivering 7,000 pounds — for stability.

If module separation were to fail after the ejection handles were pulled, pulling a severing and flotation handle would separate the unit from the aircraft in flight. As the rocket motor wouldn’t be activated in this procedure, the module would have to rely on gravitational or aerodynamic forces to separate it from the jet.

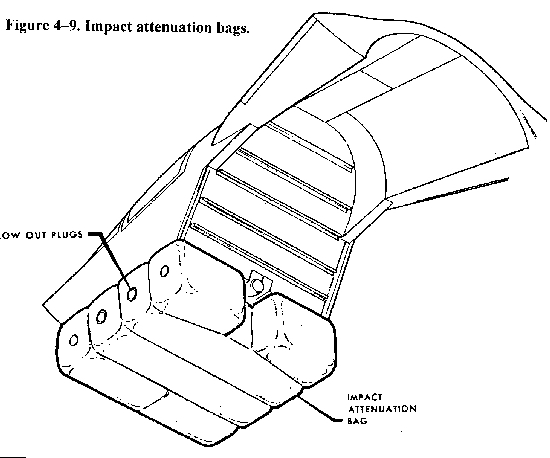

Once free from the aircraft, the module is stabilized and slowed by a brake chute. A 70 foot diameter recovery chute is deployed when the aircraft decelerates to 300 knots and descends below an altitude of 15,000 feet. When the module levels out, underside impact attenuation bags are inflated. On landing, self-righting bags on the top of the module are also deployed so that the pod does not capsize if landing in water. Aft flotation bags and additional buoyancy bags could be provided by pulling an auxiliary flotation handle.

If the aircraft ended up ditched in water, with the escape module still attached, it could be separated from the jet by pulling the severance and flotation handle, providing crew members with shelter and emergency oxygen until rescued.

The ejection module was first used on October 1, 1967. Two General Dynamics contractor pilots flying F-111A 63-9780 over Texas were forced to eject when the aircraft experienced a hydraulic failure and became uncontrollable. Ejection was initiated at 28,000 feet, and neither pilot was injured. A picture of said module can be seen below.

Some pilots experienced issues with the modules during ejection, such as the attenuation bags failing to properly work as well as delays when activating the chute. As Col. Rob Kyrouac describes in the video below, ejection was not always silky smooth.

“You know, many people that I’ve heard tell ejection stories… it’s about their heroic efforts… mine is not that, mine is riddled with oopsies. So [on] 22 September 1993, flying out of Cannon Air Force base New Mexico [in an F-111]… bearing fails, blades contact the side of the engine and they start shearing off and flying in all directions. Unfortunately for us one of those directions was right into [the] fuselage tank so now you have an engine fire being fed by 27,000 pounds of fuel.

I told the wingman hey we’re gonna have to eject… huge kick in the butt, I mean they tell you about this… as soon as we launch because I’m not in body position my chin hits my chest at an instantaneous 20g [of force] so instantly I knew I had errored because now I’m in just shooting pain up my upper back into my neck. It’s like being in a traffic accident, I mean it happens in a split second.

Eventually we hit [the ground] and that was a pretty violent impact, our legs flew up [and our] shins hit the underside of the dash. We both ended up with pretty good bruising there but, oddly enough didn’t re-injure or injure my back more than I had before.”

Soon after initial testing began, the Air Force’s aforementioned push to fast-track the process of demonstrating the Aardvark in combat in Southeast Asia became a priority. In the summer of 1967, six test aircraft were transferred to Nellis Air Force Base, Nevada, for further experimentation ahead of the combat deployment of production F-111As. It was initially decided that February 1, 1968, would be the in-theatre arrival date of the F-111A.

Two programs were launched at Nellis in order to achieve this goal. The first, Project Harvest Reaper, began in June 1967, and was designed to identify lingering problems with the test aircraft that needed ironing out. On September 24, 1967, the first production F-111A, serial number 66-0013, arrived at Nellis — flown from Fort Worth by Col. Ivan ‘Ike’ Dethman. A World War II veteran commander, Dethman headed the training unit which would generate personnel for the deployment to Southeast Asia. From there, new F-111As began to be delivered to Nellis.

Various modifications were made to Nellis’ F-111s under Harvest Reaper, including painting their undersides in FS 34102 Green, as opposed to the factory-finished FS 36622 Grey, to reduce night-time visibility. Purpose-built McDonnell Douglas BRU-3A/A bomb racks, designed to reduce drag, were made available. During operations in Southeast Asia, the racks typically held up to six 750-pound M117 general-purpose bombs with MAU-91 high-drag fins used for low-level release profiles.

The second program, Combat Trident, began in July 1967, and was designed to train an initial cadre of crews to fly F-111As in combat. For pilots, getting to know the intricacies of operating the aircraft, particularly the pre-production models, was something of a challenge, especially concerning the notoriously finicky TF-30 engines. As Hodges recalled:

“When we first got out to Nellis, none of us knew much about the new F-111. The only knowledgeable ones were the guys that had been testing it out at Edwards AFB. The ones we had to fly were some of the pre-production models and were awful.

My first flight, in the right seat, was memorable and almost a disaster. When my pilot took the active runway and ran both engines up to full power, both compressors stalled and blew fireballs out the ends of the aircraft. I asked him what was going on and he responded that it was normal for this to happen. I had 500 hours in the F-4 Phantom and had never seen a compressor stall!

He ran the engines up again and the same thing happened. By this time, I was ready to taxi this thing right back to the maintenance guys and let them have it. But once again we lit the burners and this time there was no bang.

We flew up to the Nellis bomb range and as he was showing me the area, we heard a loud noise and both windscreens became impossible to see out of. We could hardly see anything that was dead ahead which forced us to fly back to base using full flaps at about 230 knots. Our approach was flown in a full crab, so my pilot could see out the left hatch.

When we got back on the ground, we found that we had been hit by large hailstones from a storm that we never saw. The hail also punched holes in the leading edge slats as big as your thumb. We had survived the training period and the next step for us was to take the F-111 to Vietnam.”

Despite the hesitancy of many pilots to fly the “controversial F-111,” as Marquardt recalled, on March 15, 1968, six F-111As — serial numbers 66-0017, -0018, -0019, -0020, -0021, and -0022 — departed Nellis on the 20-hour, 7,000-mile journey to Takhli Royal Thai Air Force Base (RTAFB) in central Thailand for what was termed Combat Lancer. The aircraft from Detachment 1, 428th Tactical Fighter Squadron (TFS), only stopped once on route at Andersen Air Force Base, Guam, for refueling.

On arrival at Takhli RTAFB, Dethman informed the press that the deployment was for a “mission, not for a test.” The pilots had just eight days to get accustomed to the base before bombing missions would commence.

The first of those missions took place on March 25 in the relatively low-threat area of Route Pack 1 at the southernmost extreme of North Vietnam. Leading the Commando Nail mission in 66-0018, Dethman and Capt. Rick Matteis dropped M1117 bombs on an arms buildup on Tiger Island, located on Vietnam’s north-central coast. A further three aircraft sorties were flown that night.

However, it was not long before the first F-111A was lost. On March 28, ‘Omaha 77’ (66-0022), along with its pilots Maj. Harry McCann and Capt. Dennus Graham, ended up losing radar contact with airborne command at around 8,000 feet as they were flying back into Thailand from the Thai border. The jet flew into a heavy storm — what exactly downed it remains unclear.

Then, on March 30, Marquardt and Hodges were forced to use the escape module of 66-0017 while flying ‘Hotrod 76′ at around 10,000 feet over Thailand in pursuit of a target in North Vietnam. Hotrod 76 ended up pitching violently after the structural failure of a valve in the stabilator control system — stabilators are fully movable aircraft horizontal stabilizers. Unable to gain control, the crew elected to eject.

When the wreckage of 66-0017 was successfully located near the Mekong River town of Mukdahan in Thailand, a thorough investigation into the crash was conducted. While it was first thought that a tube of sealant had accidentally become wedged into the flight controls, it was later proven that issues with the stabilator control system were to blame for the incident.

Following the loss of 66-0017, operations were briefly suspended, although it was not long before F-111As returned to the skies. Once they did, a series of flawless night missions were performed for 22 days straight.

A third F-111A crash came later in April. Two new F-111As, serial numbers 66-0024 and 66-0025, arrived at Takhli RTAFB from Nellis on April 5. Flown by Lt. Col. Ed Palmgren and U.S. Navy exchange pilot LCDR David Cooley, 66-0024 was lost on radar by airborne command on April 22 at around 200 feet while passing over heavily defended areas in Laos. Its wreckage was never found. It was assumed by the Air Force that a failure of the stabilator control system was the cause.

On May 8, another F-111 was lost — at Nellis AFB, rather than in Southeast Asia — due to a faulty tail actuator, a small welded steel part in the hydraulic actuator for the aircraft’s horizontal tail. Later that month, the five surviving F-111As at Takhli were grounded until June 21. After that, they were initially restricted to training flights within Thailand. When combat missions resumed in July, they were conducted against easier Route Pack 1 targets. Combat Lancer ended a few months later when the five surviving F-111As returned to Nellis on November 19, 1968.

Although the 428th TFS lost three F-111s during the aircraft’s operational debut in Vietnam, the Air Force was satisfied that the jet had successfully demonstrated its capability to rapidly strike virtually any target in adverse conditions — flying 60 percent of missions in poor weather. F-111As returned to Vietnam in 1972 as part of Operation Linebacker. During the 1980s, F-111s were used for airstrikes against Libya during Operation El Dorado Canyon, and they later participated in Operation Desert Storm during the 1990s. EF-111 electronic warfare aircraft were also used during Operation El Dorado Canyon and Operation Desert Storm, and were later deployed in other areas of the middle east and Europe.

By the time the swing-wing F-111 was retired from the U.S. Air Force — the aircraft continued flying with the Royal Australian Air Force (RAAF) until December 2010 — it was rightly judged as one of the most capable strike aircraft of the entire Cold War. However, the remarkable image of Maj. Marquardt and Capt. Hodges in the escape module of their jet in 1968 recalls the troubled combat debut F-111s had to overcome and, for many pilots, the life-saving ejection system of the aircraft.

Of course, other U.S. Air Force aircraft explored the concept of escape modules with differing levels of success. The XB-70 Valkyrie, the prototype for the B-70 supersonic strategic bomber, featured individual escape capsules similar in concept to the B-58 Hustler’s and a larger module was also being looked at. Test pilot Al White, seen below, was saved by one of the XB-70’s capsules during an infamous mid-air collision mishap on June 8, 1966, although his fellow pilot Joe Walker died during the incident.

Three of the four B-1 Lancer prototypes had escape modules very similar to the F-111, just much bigger. On August 29, 1984, pilots flying the second B-1 prototype were forced to eject over the Mojave Desert, after two master control warning lights and a center of gravity warning light were illuminated. The escape module deployed successfully, although there was a problem with launching its parachute. The capsule hit the ground on its right side, igniting a bush fire. Chief test pilot Douglas Benefield was killed on impact, and two others were seriously injured.

If nothing else, the F-111 proved that big and complex safety escape modules could work operationally on combat aircraft, and, despite its issues, the F-111’s was a remarkable piece of engineering in its own right.

Contact the author: oliver@thewarzone.com