The first known prototype of the Model 437 from Northrop Grumman subsidiary Scaled Composites has flown. The design has been in development as an advanced “loyal wingman” air combat drone since at least 2021, but this initial example interestingly emerged earlier this month with a cockpit, as you can read more about in The War Zone‘s previous reporting here.

See the update at the bottom of this story for new information.

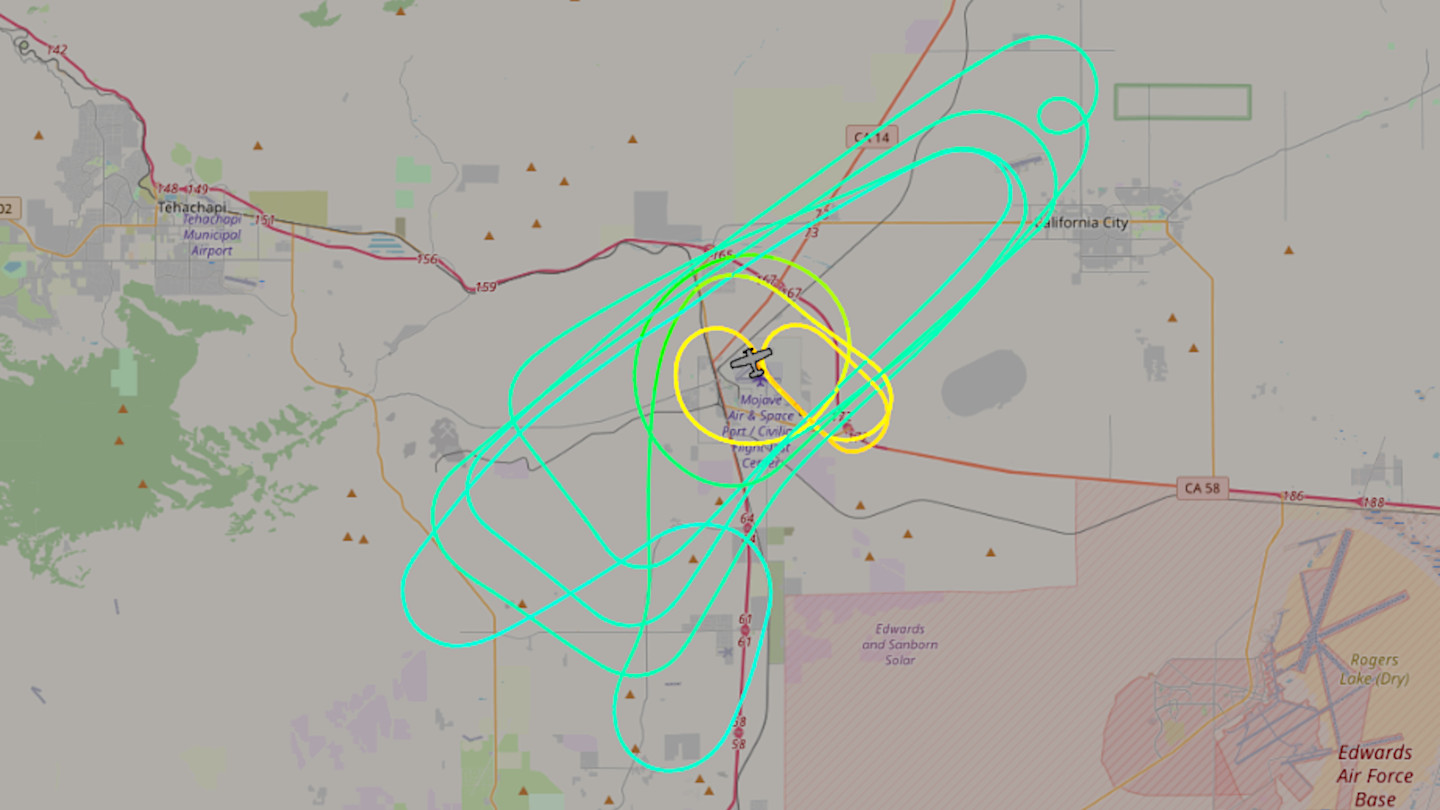

Friend of The War Zone Matt Hartman caught the aircraft, which carries the U.S. civil registration number N437VN, flying for the first time from Mojave Air And Space Port in California, earlier today.

Publicly available online flight tracking data also shows N437VN’s flight.

Details about the Model 437 and its development status remain murky, although it was designed to fulfill some of the U.S. military’s advanced unmanned combat aircraft needs, most likely including the Collaborative Air Combat (CCA) mission set. Exports are also a growing possibility for at least some of the USAF’s CCA aircraft. The War Zone has reached out to Northrop Grumman and Scaled Composites for more information about the aircraft, including background on this test article’s crewed configuration.

“The aircraft, which sports the registry N437VN (certified in January of this year, according to FAA data), features a bowless bubble canopy, a pointed nose with a semi-trapezoidal fuselage, mid-set swept wings, a long dorsal air intake that hugs the rear of the canopy, a distinct chine-line that wraps around the airframe, trailing-link landing gear, and a splayed v-tail adorned in a camouflage pattern. The aircraft also features a round exhaust and a long air data probe, which is customary for initial flight testing and is also visible on its nose. Once again, it looks very much like the Model 437 renderings, just with a bubble canopy. Overall, paired with its small size, it has a very futuristic, almost movie-prop-like look.”

“As we laid out in our initial report on the Model 437 concept art, this design clearly evolved from Scaled Composites’ Model 401 demonstrators, which themselves evolved, at least inspirationally, from the company’s ARES demonstrator. The Model 401 is also now touted as having the potential to be offered alongside the Model 437 in an unmanned production configuration.”

Back in 2021, the Model 437’s expected specifications were also described as such:

“With regards to the new Model 437 design, it is also expected to have a range of some 3,000 nautical miles when carrying a load of 4,000 pounds of fuel, and will be able to cruise at around 0.8 Mach, according to Aviation Week. The drone has an internal centerline payload bay that is designed to carry up to 1,000 pounds of stores or other systems, as well. The outlet said that a pair of AIM-120 Advanced Medium-Range Air-to-Air Missiles (AMRAAM) or a side-looking radar imaging sensor were two possible loadouts.“

Whether or not those design goals have changed since then is unknown. Making a prototype that is piloted, or at least pilot-optional, offers major benefits for flight testing and other development work, especially given current restrictions on where and when full uncrewed designs can operate within U.S. airspace. An optionally crewed configuration could have operational utility, as well. You can read more about all of this in our previous piece on N437VN.

With N437VN now flying, hopefully more information about the Model 437, and Northrop Grumman and Scaled Composites’ current plans for the design, will begin to emerge.

UPDATE: 4:20 PM EST —

Scaled Composites has now confirmed in a press release that N437VN “is a crewed variant of the original [Model 437] concept” that is also now named Vanguard.

“The Model 437 Vanguard is… powered by a single Pratt & Whitney 535 engine with approximately 3,400 pounds of thrust. The aircraft has a wingspan of 41 feet and is 41 feet long with a gross takeoff weight of 10,000 pounds,” according to Scaled Composites. “After completion of envelope expansion, the M437 Vanguard will have a range of approximately 3,000 nautical miles and an endurance of 6 hours. The aircraft can carry up to 2,000 pounds of payload in multiple locations including an internal weapons bay sized to accommodate two AIM-120s.”

“Scaled Composites leveraged extensive experience in rapid design, fabrication, and test of experimental aircraft to develop the Model 437 Vanguard,” the press release from the Northrop Grumman subsidiary adds. “This included a clean sheet aircraft design, aerodynamic and structural analysis, fuselage and empennage fabrication, aircraft assembly, systems integration, and ground and flight test execution. Northrop Grumman defined, developed, built and verified the removable wing assemblies using advanced digital tools and processes as part of their Digital Pathfinder effort.”

Northrop Grumman has put out its own press release focused on the Digital Pathfinder aspect of the development of the Model 437 Vanguard, which it also described as a “technology demonstrator.”

“Development began in the fully connected digital ecosystem with Northrop Grumman, the customer and supplier users collaborating to develop, analyze, build and test the wings ahead of the Model 437’s first flight, which occurred on August 29,” according to the release. “The Digital Pathfinder project demonstrated how the company’s fully digital engineering ecosystem reduces engineering rework, accelerates schedule and reduces costs, offering advantages to customers on future aircraft programs.”

“By utilizing real-world experiences gained on programs, including the B-21 Raider, the company continues to evolve its collaborative digital ecosystem, which connects the company, customers and supplier partners through the design, development and test phases on a variety of current and future programs,” it continues. “The digital ecosystem cut engineering rework and redesign to less than one percent, compared to the 15-20% experienced using traditional methods. The demonstration also leveraged high-fidelity models combined with rigorous and approved model validation schemes to reduce requirements for ground and flight tests. Looking forward, these models show the potential to significantly reduce the workload required to determine airworthiness, offering further cost and schedule savings opportunities.”

“Through Digital Pathfinder, Northrop Grumman’s high integrity digital thread connected engineers, customers and stakeholders in a virtual environment, allowing them to proactively foresee and solve the types of problems that typically plague acquisition programs up front and early — greatly improving program performance,” the release adds. “The demonstration also utilized advanced manufacturing techniques, including the production of a titanium structural bracket using plasma arc energy deposition. The application of this innovative additive manufacturing technique to form a titanium part is believed to be a first in the defense industry. At the same time, the Digital Pathfinder project applied advanced techniques to reduce the requirements for hard tooling while improving first time quality and reducing manufacturing rework.”

Contact the author: joe@twz.com