A fix of a kind has been found for problems with the F-35’s vital Tech Refresh 3 software, or TR-3, which had seen production deliveries suspended for around a year. Deliveries of the stealth fighters will resume “in the near future,” clearing a backlog of jets sitting in storage, although the TR-3 is only installed in what’s described as a “truncated” form, raising questions about when the F-35 will actually be able to make full use of the long-awaited Block 4 improvements that this software underpins.

The F-35 Joint Program Office announced yesterday that Lt. Gen. Michael J. Schmidt, the F-35 program executive officer, approved the use of the “truncated” TR-3 software on July 3. This means that more than 90 (perhaps as many as 120) F-35s that had been manufactured but then put into storage at Lockheed Martin’s Fort Worth, Texas, plant can be delivered. These jets are destined for both U.S. and foreign customers.

In the meantime, the TR-3 software remains in flight testing, with the aim of achieving a long-term fix.

Schmidt’s decision was made, the JPO explains, “after extensive coordination with the services, Joint Strike Fighter Executive Steering Board, pilots, maintainers, and industry.”

As we have reported in the past, the first flight of an F-35 test jet with a version of the TR-3 backbone took place in January 2023.

Production jets then began to be completed with TR-3 processors and related hardware. However, TR-3 has suffered numerous delays that have contributed to significant cost overruns in the program. The ongoing issues meant that deliveries of these aircraft were suspended in July 2023.

As of December 2023, it was reported that the development of TR-3 would be completed sometime between April and June of 2024 — after this, the same TR-3 enhancements would have to be incorporated into the existing jets.

By January of this year, Lockheed Martin was saying it didn’t expect F-35 deliveries to resume until late this summer, but it also confirmed that thought was being given to accepting jets before then, without the fully validated TR-3 hardware and software. This is the workaround that Schmidt signed off earlier this month.

In March, when the F-35 was finally been cleared for full-rate production, 17 years after the aircraft first took to the air, customers were still not accepting new aircraft.

There’s no doubt that TR-3 is of fundamental importance to the F-35 enterprise’s future.

Simply put, TR-3 is needed to support the forthcoming enhancements for the F-35 collectively known as Block 4. TR-3 has been described as the F-35’s new ‘computer backbone,’ since it promises to provide 25 times more computing power than the existing TR-2 computing system.

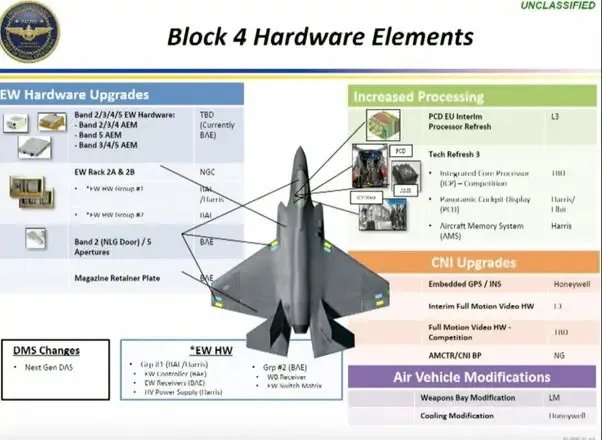

Block 4 will give the F-35 advanced new capabilities, including much-expanded processing power, new displays, enhanced cooling, new EOTS and DAS electro-optical sensors, and a range of additional weapons that will greatly help the aircraft meet its potential. A very significant aspect of Block 4 will be a new radar and electronic warfare suite. In the past, the boss of Air Combat Command has even gone on record to say that the electronic warfare improvements are the single most important advance enshrined in Block 4.

Separate from TR-3, but also critical for enabling Block 4 capabilities are upgrades to the Pratt & Whitney F135 engines that power all variants of the Joint Strike Fighter, as well as power and thermal management systems. Around the engine issue, too, there has been controversy, as you can read more about here.

Obviously, restarting F-35 deliveries is a critical step for the program, although we don’t have much, at this point, of how the incomplete software will affect the capabilities of the jet and the realization of Block 4. We have approached the Joint Program Office for more details on this.

What we do know is that Schmidt was provided with enough evidence that the truncated software is reliable and safe enough for regular operations, something that was not obvious in the past. Even in May, there were reports of test pilots having to reboot the software multiple times during the course of a sortie.

The yearlong delivery hiatus has had a major knock-on effect on the program, both for U.S. and foreign customers.

Lockheed says it will be able to deliver F-35s at a rate of one aircraft per day, but even if it meets that target, it will take more than a year to catch up on deliveries of the stored jets. At the same time, new F-35s continue to come off the production line, making it even harder to address the backlog.

With deliveries on hold, plans to establish new squadrons, train new crews, and accelerate the replacement of older aircraft types have been impacted across the F-35 user community.

An example of these problems came to light late last month, when Denmark announced that the six F-35As it uses for training at Luke Air Force Base, Arizona, will be relocated to Denmark, to help make up for the delivery shortfall of new production aircraft. The jets are badly needed back home in Denmark not only to train crews there but to allow the retirement of the F-16, some of which have been promised to Ukraine.

Looking further ahead, there are signs that the Joint Program Office may also be scaling back its Block 4 ambitions, at least to some degree.

Testifying to the House Armed Services Committee (HASC) in April, Schmidt suggested that the Block 4 upgrade will be “reimagined” and that some elements will be delayed until the 2030s.

Schmidt also painted a fairly bleak picture of how TR-3 has been rolled out so far, admiring that it “has taken far too long to deliver.”

Schmidt explained that the maturity of the hardware design was “a significant complicating factor in software integration.” The hardware problem is driven by “low manufacturing yields of parts necessary for aircraft production.”

“We also find ourselves using software to overcome hardware design maturity challenges,” Schmidt added.

Therefore, while the software architecture for TR-3 has been judged as “solid,” it has been let down by the fact that the underlying hardware is not fully ready to support it. As a result, the F-35 program “will continue to struggle with software integration efficiency.”

Even with deliveries resuming soon — according to reports, they could even have commenced yesterday — TR-3 still has the potential to yield more problems and delays.

As Schmidt observed, “Future risks hinge upon whether TR-3 will require additional incremental software releases to test and implement critical fixes. If risk manifests in labs or flight test, TR-3 may require additional software releases (taking between two and six weeks per release).”

To try and keep things moving, the Joint Program Office and the U.S. military have come up with two separate TR-3 software releases.

“The first release (40P01) is a truncation of the TR-3 software at a point when the code is stable, capable, and maintainable to deliver TR-3 configured aircraft for use in combat training, but it is not until the second software release (40P02) that full combat capability is realized.”

Once new and previously stored F-35s start to be delivered to operational units, they will, initially at least, be restricted to training, circumstances that Schmidt observes are “not ideal.”

When the next TR-3 software release (40P02) comes online, it will provide “significantly more combat capability.” The specifics of this are unclear and, once again, we have reached out to the Joint Program Office for more.

Overall, signing off on a truncated version of the TR-3 software does address the problem of having a growing number of F-35 airframes sitting dormant — there have been questions about the liability of those jets, too, should they be damaged by a storm, for example, with the government likely having to pay for any repairs.

At the same time, delivering F-35s with the interim software does at least provide a boost to training squadrons, allow new units to be established, and provide familiarity with TR-3 — albeit not in its definitive configuration.

All this comes with global demand for F-35s soaring, driven in part by recent geopolitical events and new and emerging threats.

However, the decision to resume deliveries is not without risk and while the Block 4 upgrade has been billed as a game-changer for the jet, it looks like it will be some years before the full scope of these improvements can be exploited.

Contact the author: thomas@thewarzone.com