The B-52 Stratofortress is arguably one of the most iconic flying machines ever created. For the U.S. military, it is so much more than that. It serves as the backbone of the aerial leg of America’s nuclear deterrent triad and has morphed throughout the years to match the needs of the Air Force at the time. From standoff missile truck to close air support platform, the B-52 has done far more than its original creators could have ever dreamed it would do. It’s now set to soldier on at least into the back half of the century, taking on new roles as hypersonic missile truck — and who knows what else — in an upgraded form.

The thing most don’t think about in regard to the B-52 is just how many generations of airmen have put blood, sweat, and tears into keeping it in the air day-in and day-out. With the youngest B-52H now hitting 60 years old, there were airmen scrambling to generate sorties on these same jets that called John F. Kennedy their Commander-in-Chief. The fact that they still fly so reliably — they are more dependable by a significant margin than their newer B-2 and B-1 brethren — is a testament to the guys and gals on flightlines and in hangars, putting in long hours to keep these ancient flying beasts motivated to complete their critical missions. They are the true unsung heroes of the B-52’s incredible story.

At the tip of the B-52’s support team’s spear is the crew chief. Enter John Brehman, who was a young kid from Chicago fresh out of high school when he enlisted just prior to the world-changing events of 9/11. He went on to serve until the middle of the decade that would be dominated by the Global War On Terror — a strategic shift that would see the B-52’s mission be revamped once again. Brehman was part of a long lineage of young Americans whose mission was to make the B-52 fly. For an aircraft that was already nearly a half-century old at the time, massive in proportions, and sporting eight turbofan engines, that is not an easy task, as we are about to find out.

Below is our extensive Q and A, but before we start, I would check out this previous post that features a great tour of the B-52. It will make this piece a far richer read.

What exactly does a B-52 crew chief’s job entail?

Very generally, a crew chief is responsible for the general maintenance, inspections, and servicing, as well as launch and recovery, of their aircraft. Maintenance can mean everything from changing brakes to changing cockpit light bulbs; inspections from pre-flight to extensive tear-down in Phase; servicing from a 310,000 lb refuel to refilling liquid oxygen tanks.

B-52 Bomb Squadrons (BS) at Barksdale Air Force Base (96th, 20th, and 11th, and the 93rd Reservists) utilized a dedicated crew chief (DCC) system — usually, an E-5 or young E-6 is the DCC, with an E-4 as assistant DCC (ADCC) and a couple of E-3s or below also working that jet. Ideally, the same people work on the same jet for years, getting to intimately know the quirks and specific details of an individual plane. This is certainly true of the DCCs themselves, but maybe less true of the ADCCs.

If your airplane is flying on a given day — maybe two to three times a week for a couple of weeks and then not again for a few weeks — generally the DCC and an E-3 will launch it, coming in eight hours before launch, which would usually be between 8 and 10 AM. The ADCC and the other E-1 recover it in the afternoon or evening. Training flights would often be eight or more hours long, I imagine to semi-simulate combat ops. On the many other non-flying days, you’re helping everyone else with their planes. There was rarely a shortage of work.

When I was there, the Air Force moved away from individual bomb squadrons having maintenance (MX) sections, and went with the more generic 2nd Aircraft Maintenance Squadron for the 2nd Bomb Wing, but nothing really changed. The same MX personnel were still assigned to the same bomber squadron and the same planes. That, as with many other things, may have changed since 2005.

As an aside, crew chiefs were “in charge” of MX, but many other specialists contributed every day to the airworthiness of a jet: hydraulics, electrics, avionics, life support, comms, engines. The list goes on. Unless there’s a scheduled task from a given section, we would be the ones to call those specialists, either via a crew request or because we found something amiss.

What are the major differences between being a crew chief for a modern tactical jet, like an F-16, and a huge early Cold War-era strategic bomber like the B-52?

I don’t really know the differences, but I would speculate that modern jets, like commercial jets, have fault sensors and can tell the mechanic what the issue is, or are small enough that one person can handle most tasks. Everything on the MX side of a B-52 is visual. You’re checking steam gauges and sight gauges in the wheel and flap wells for the six hydraulic systems. You’re putting a tire pressure gauge on 10 tires. You’re repositioning a stand eight times just to check the oil. Etc.

Rarely did we work alone on a B-52. There was a lot to be done and it all took time.

How does one train to be a crew chief on a B-52?

The training was actually pretty simple. I spent about two months at Sheppard AFB in Texas, mostly dealing with classroom safety instructions. They have a G-model there with the vertical stabilizer cut off so the Russian satellites know it’s not an active bomber, but I don’t think we touched it to do any practice maintenance. We just used the aircraft familiarity training. When I got to Barksdale AFB, of course, it was different. Like any job, you sort of jump into any situation you can, and get respect by being willing to do anything. I was also blessed with an outstanding supervisor (my DCC), who quizzed me randomly when we had time and was seen as one of the most knowledgeable guys on the flightline.

The B-52 crew chief as a job is sort of a dead end. Either one cross-trains after six or so years, or they stay in Shreveport (or — God forbid — Minot) and likely become an expert on the aircraft. No old-timer knew everything, though. Every plane we had (built 1960 and 1961) was older than anyone working on it, and even the 20-plus year guys would be called out of the office here and there to see something new.

How does the crew chief on a B-52 interact with its flight crews and its maintainers?

As a young buck back then, I didn’t interact too much with the crew, to my regret. I was focused on not screwing up. Those butterbars (new officers) and lieutenants who were training weren’t much older than me. They were the ones we’d see from the hangar bouncing ‘our’ aircraft on the runway doing touch-and-goes.

We’d say, “It takes a college education to break a plane, and a high school education to fix it.”

The DCC and more knowledgeable maintainers had a friendly relationship with the crew most often. The DCC, launching the aircraft, would usually know the aircraft commander, and there was a lot of implicit trust the crew gave us. I learned that later on, after I gained the knowledge and experience to be in charge of a launch myself. Most often, they ask any question and go with whatever you have to offer them.

The youth of some of the training flight crews made for funny moments. I never saw it myself, but a young LT inspecting a leak in the bomb bay, inclined to touch and smell the liquid in question to determine the source, may have had crew chief piss on his fingers. Rarely was there an asshole crew member. Sometimes crew members would leave important items in the cockpit, like a headset or document case. The CC would keep it for them and often would be rewarded with a case of beer — a tradition.

How reliable were the BUFFs (Big Ugly Fat Fuckers — or Fellows) when you were crew chief on them?

We never said BUFFs, so that’s funny to hear. I loved my jet, “Balls Eleven,” the flagship of the 11th Bomber Squadron, so I didn’t consider it an ugly plane. Maybe that’s just me! Anyway, pretty darn reliable, I think. We had stats displayed on a physical board, updated weekly, driving into the Bossier City entrance of Barksdale with each bomber squadron’s recent reliability. I think most were around 85 percent-ish, albeit that’s stateside.

I know we were more reliable than B-2s by a bit and by B-1s by a good deal, for the most part. From what I remember, the Bone’s reliability was in the 60 percent a lot of the time. Sort goes to show why the Air Force is keeping the B-52 around.

Walk us through a typical launch and recovery of a B-52. So, launch. As a crew chief, you’d get there eight hours prior — let’s say midnight, for an 8 AM flight. All the servicing should be done and good. The aircraft should be good to go. Fueled up. You’re not changing a tire at 2 in the morning, of course. So you’re going through the pre-flight checklist, which is extensive, but easy as long as nothing happens, which it likely wouldn’t — double-checking stuff for your own eyes, basically, so when you greet the flight crew you have absolute confidence in the jet. You’re running a flashlight over accumulator pressure gauges and hydro reservoir sight gauges, checking for leaks on the landing gear.

Hint: If you know your aircraft and know there’s a training crew that’s going to wonder why there’s a single drip of hydro fluid on the main landing gear strut, keep a rag on you and wipe it right before the crew van shows up. And, of course, know the exact drip limits allowed by the tech orders, so you can confidently tell this super-cautious new second lieutenant or this full-bird colonel getting out of the office for the first time in a month, “It’s within limits.”

We work over the plane with flashlights and determine it’s fine. Time to transcribe forms, my least favorite activity. Maybe it’s electronic now. Hopefully, it is. Every fault that is found has to be written up. Every corrective action taken has to be written up, with the annotated tech order reference. Everything signed off can be set aside, taken out of the aircraft forms, which actually stay on the aircraft when it flies (again, maybe changed since 2005), but all the existent items have to be carried forward for the aircrew to review. It’s like office work.

Now we’re ready, and we’re at the aircraft when the aircrew pulls up two hours before scheduled takeoff. We have things nice and tidy, which means everything from pushing the chocks a bit forward from the forward gear (there’s nothing more embarrassing than not being able to remove a chock when everything else is golden and engines are running, but there’s pressure on an offending chock), to having the ejection seat straps set off to the side so the crew can easily get in their seats.

We talk to the crew — they review the forms. They ask about outstanding discrepancies — we explain any issues. They go up the hatch after their individual outside inspections and get set up. We have an air cart and a generator hooked up to the aircraft — attached to the #2 pod, 3 and 4 engines — because the B-52 has no onboard auxiliary power unit (APU). There are two crew chiefs in the launching crew — one on a headset talking to the aircrew, the other to follow instructions. The generator is pretty much always running, but unlike an actual APU, our air cart doesn’t supply air conditioning. On super hot days, or if a VIP is flying, they’ll haul an enormous AC cart out to the jet and run the foot-diameter insulated tubes through the hatch or through the cockpit windows.

The aircrew will start engines 3 and 4 off of the air cart we have. That means they have low-pressure air, one hydraulic system, and one generator online. Keep that in mind for cart starts. On the ground, the non-wired crew chief is in front just looking for anything abnormal. If it’s sorta crazy and only lasts for two to three seconds, it’s “normal.” You do not want to freak out flight crews by reporting flames that aren’t sustained. So the engines start normally, as they usually do, and that’s signaled to the crew by hand and also through the headset.

They start the rest of the eight engines, and other vehicles, which have crew chiefs and have been watching us launch, swoop in to take away first the air cart and a bit later the generator. The crew cycle and check flight surfaces and close the bomb bay doors. The headset-wearing crew chief confirms these movements. If any crew member has issues with their equipment, the aircraft commander, in the pilot’s seat — also generally our point of contact on the headset — will request specialists or tell us what to do.

Then comes the fun part, when they’re ready to go. There are two of us, so one wishes the crew well as they unplug from the intercom system in the wheel well. Each crew chief pulls a four-foot chock out of the way of the forward main landing gear, dragging it to the aft gear so it’s not a factor at all. Then we run out to our respective wings to make sure everything is clear. Remember that there are eight running engines and you’re running up the fuselage and away from the pilot’s view. Then we snap-to, give them a salute, and touch the wingtips as it taxis by.

Launching a plane generally wasn’t hard work, but it was very rewarding if it was ‘your’ plane. Even if it wasn’t, one knew the work that went into getting a B-52 off the ground, and it was still a great feeling.

Everyone swarmed a B-52 after a mission. For crew chiefs, the ADCC might ask the crew questions, maybe not. At this point, it’s the evening and everyone wants to get shit done: Swing shift (3 PM-ish to midnight-ish) wants to start work so they can end work. The aircrew has been doing a difficult job since their pre-flight briefings at 6 AM. Day shift sucks ass and is as lazy as possible. But yeah, all the servicing and MX generally happens soon after landing. A boost to your ego might happen if you find that, as you show a B-52 crew where to park their aircraft, you nail it with hand directions. That’s a nice feeling, to get it right immediately.

First and foremost, after engine shutdown, you safe the ejection seats. You can’t work in an environment with unsafe ejection seats. These are not zero-zero (zero airspeed, zero altitude) ejection seats. In other words, they can’t save the crew safely without some forward speed and altitude. To punch out, you rotate and depress the handle, and the lip of the ejection hatch is exposed to the airstream. If there’s no airstream, or you’re in a lower compartment with little altitude, it’s over.

There’s also an actual rope kept in the cockpit — DO NOT grab the rope and jump! At least that advice was given to us in training. It’s one of those features that exist but probably has never been used. Anecdotally, we heard people have broken legs in their hurry to get out. The “escape route” was the no. 3 cockpit window, the only window that opens, or somehow climbing out of the hatch above the election seat by twisting torque tubes to release and then lift the hatch.

After that, it’s your basic oil servicing, checking tires and brakes.

And of course, then there is also the drag chute.

It’s a huge part of the crew chief’s job. Every recovery involved reinstalling a drag chute. It’s a 200-ish pound parcel. It’s a key piece of the B-52 — the brakes are sturdy, but not meant to hold up for so long. Also, the aircraft is very heavy. Pilots pop the chute every time; it’s part of a normal landing. There’s a shop, of course, for re-packing chutes.

So, part of the post-flight would be to re-install a drag chute. This would involve getting a drag chute stand, if one is available, and hauling it across the flightline. And it takes four-ish people to put the chute in and rig it and the drogue chute, which is a little spring-loaded canister attached to the cockpit via a cable that runs the length of the fuselage. There’s a winch on the drag chute stand to pull up the chute from the ground to get it into the tail, but usually, it was easier to haul the fucking thing up a bunch of steps from a different stand.

The pilot chute pops out of this roughly 18-inch by 10-inch can. It’s mounted on the door of the main chute compartment. The aircrew pulls the handle and the cable pops the door open. That action also pulls a pin on the pilot chute can. The pilot chute flies out via spring, catches air, and pulls the enormous main chute out. After use, after they clear the runway, they cycle the handle to release the main chute — which is secured by a different, much heavier pin — that attaches to the main and to the drogue. The airplane keeps the drogue chute canister and the bag.

I’m making it seem more complex than it is. Everything released is recovered near the end of the runway by the people in the chute shop, who then inspect, repair, and repack it. One day-shift crew chief duty was to visit the chute shop and load up the truck for every flying aircraft that day, chute reinstallation being one of the last activities after recovery. A guy in the cockpit would cycle the handle to make sure everything works correctly and the main chute jaws-locking mechanism is open for installation, and then closed for use by the aircrew. Then the chute would be reinstalled.

The truck driver was usually a seasoned tech sergeant. This is the AF equivalent of lower-level NCOs getting it done in pretty much every war movie. They ran the shift with a grease pencil and a plexi board with aircraft status and needs on it. Every job and every request flowed through them. During the day, they’re doing the routine tasks and routine maintenance and getting ready for recoveries. Come swing shift, they’re harried — every recovery crew needs a bunch of things. Mid-shift, it’s pretty low-key, they’re checking up on guys doing pre-flights.

‘The truck’ was painted blue and had benches along the sides in the back. It brought guys to and from the smoke pit and flight kitchen, brought tools, launch kits and ladders piled high to and from the aircraft, and towed things like generators and air carts and tires and jacks. A good truck driver was invaluable, and an inexperienced or bad one was borderline insufferable. You would walk a mile back to the hanger with a 40-pound toolbox rather than wait for them.

Tell us about what went into a “cartridge start” on a B-52?

We practiced cart starts, I think, once or twice a year. Not sure where the cartridges were stored, but we would get them and install them in the no. 4 and no. 5 engines during whatever exercise we were doing. Conventional and Nuclear Operational Readiness Inspections (CORI and NORI) were each 10 to 14 days a year. There was a NORI going on during 9/11, which is often left out of narratives. Many guys I worked with were at Barksdale on 9/11, and damn, they tell of seeing a huge plane come in (Air Force One), landing near B-52s loaded with live nukes, knowing that the national airspace was closed at that point. It had to be a weird feeling. And then the President makes an appearance and then took off again.

Anyway, the carts are 10 inches or so in diameter and weigh maybe eight pounds. They were always described as large shotgun shells. They simply supply a huge volume of pressurized gas into the engine in a short time to turn the compressor. The carts were activated by a circuit from the aircraft’s battery, and as such had to be protected from static electricity as much as possible, lest they inadvertently fire. The B-52 doesn’t have static wicks like modern aircraft do, so grounding the aircraft after it landed was always stressed.

There’s a port on each engine for a cartridge, so the crew could get in and go very, very quickly if need be. We practiced with engines 4 and 5 only, though, so they’d get a generator, hydraulics, and low-pressure air to start the other engines online quickly, using battery power alone. No external generator or air cart was needed, which was actually sort of weird to see. I think there was a lead-sealed switch over the applicable engine start switches when the carts were installed. Once you hit those switches, if you’ve got the appropriate settings, you will have engines running very quickly. If everything is pre-set, you can taxi out in minutes, after large plumes of smoke are blown aside quickly by engine exhaust.

As an aside, I spent a couple of weeks on temporary duty at Minot AFB in 2004. I think it was a CORI, but I’m not sure. Our little detachment did our jobs and worked out of those old alert shelters that B-52 crews would live in for weeks at a time during the Cold War — and would run out of in the movies — so you knew the threat of war was real. Run up the ramp, and planes are ready to go, probably with carts already in the engines. These were bare-bones bunkers with libraries and recreation rooms frozen in 1988 or so. Never say no to a deployment, though. It was a sometimes really interesting, if mostly boring, couple of weeks.

What are five highlights of servicing the B-52? In general, I think we took pride in how everything had to be done so rudimentarily. There were very few shortcuts. When it came down to it, we got stuff done. We had the most storied, badass airframe, and even in modern combat (Afghanistan, Iraq), the B-52 reliability rates were superior to other airframes.

I liked maintenance like changing brakes, one of the more physically demanding jobs. A bunch of guys doing heavy maintenance on a plane on the flightline was what the job aspired to be ‘about.’ For some reason, putting such a big-ass plane on jacks was cool. It was hard work but getting it done was very satisfying.

Everyone in the military knows what a B-52 is. You say “B-52 mechanic,” and people get it. Even later in life, going to school with some combat vets, there’d be some respect there, if only because it appeared to be a real job.

Deploying to tropical islands — Guam and then forward deploying to Diego Garcia — to get a Global War On Terror medal. This was the most fun and most rewarding work/play I did in the Air Force. Working on a cool plane and lying on beaches. Getting that medal also meant enhanced benefits as a veteran. Really just ridiculous how lucky I got in that regard.

Launching a plane was very rewarding. Doing the pre-flight, talking to the crew, getting the systems up and running, then marshaling them out, knowing how much work would go into each mission, and then seeing that huge plane take to the skies. Then, as soon as it lifts off, you could head home proud of what you did. It was a great feeling.

Another fun, yet uncommon, exercise was the ERCC, the Engines Running Crew Change. You’re waiting at the end of the runway, so you can see the aircraft coming in basically overhead to do touch and goes, and then pull up, as the aircrew changes out.

Let’s get to the lowlights. Everything takes forever. A plane land with 30,000 lbs of fuel and needing to fly with 310,000 lbs the next day would take many hours to refuel. If the powers that be decide that fuel tank maintenance is required, a defuel and drain might take two eight-hour shifts, using boost pumps to put that fuel into tanker trucks.

Trying to refill the liquid oxygen when it’s 90 degrees outside. When the three 25-liter tanks were full, they’d spill over. When it’s hot out, that would never happen, so you do what you can.

Let me clarify what I mean by this. Liquid oxygen (LOX) is stored at -297° F, so on a hot day, a lot of oxygen is boiling into the atmosphere before even making it into the aircraft. Also, note that the aircraft’s three 25-liter storage spheres aren’t mechanically cooled in any way. They are just large thermoses, with piping running from the aft part of the aircraft to the cockpit. So, if an aircraft is in the flying rotation, that’s a lot of LOX, and servicing time going to waste. Maybe a crew chief is spending four hours with two LOX carts to just get it up to, say, 60 liters, and they’ll have to do the same again in a day or two just to keep it ready to fly.

No APU and no air conditioning mean extra work and lack of comfort. External power was supplied via a Hobart (because of the brand name) — a 3,000-lb old beast of a towable generator that needed to be working in order to conduct much maintenance.

Every little thing might have to be serviced. No. 2 main hydraulic reservoir looks low? Get a ladder and a hydro cart. It’s pretty simple but it takes time. Another one of those situations where knowing the plane saves time and effort. Maybe the crew chief sees a main hydro reservoir come in low from a mission, but they know it’ll even out in a bit when the aircraft ‘settles,’ or if one just wiggles the spoilers, for example.

Because the jets are old, I think, lots of panels and the cowlings and so on just don’t fit well. If you’re reinstalling urinal flooring, you’re getting as many bolts as possible in, but then … maybe the rest just don’t work. And you have to sign off on that, because it’s the urinal flooring, and there’s no way anyone is doing that perfectly. So you have to know what you can pencil-whip and what needs to be worked on and/or sent up for more evaluation, just like anything else.

With something like cowling, of course, a DCC might know their own plane and know that a certain engine’s cowling is just the worst to get back on. But that can’t be helped, and sometimes you’re out there with four guys for hours trying to get certain latches to line up. That’s stuff that obviously can’t be fudged, but was a huge, huge pain, literally, as we would be putting our arms and backs into holding the lower cowling in place for as long as possible with someone else trying to close a latch.

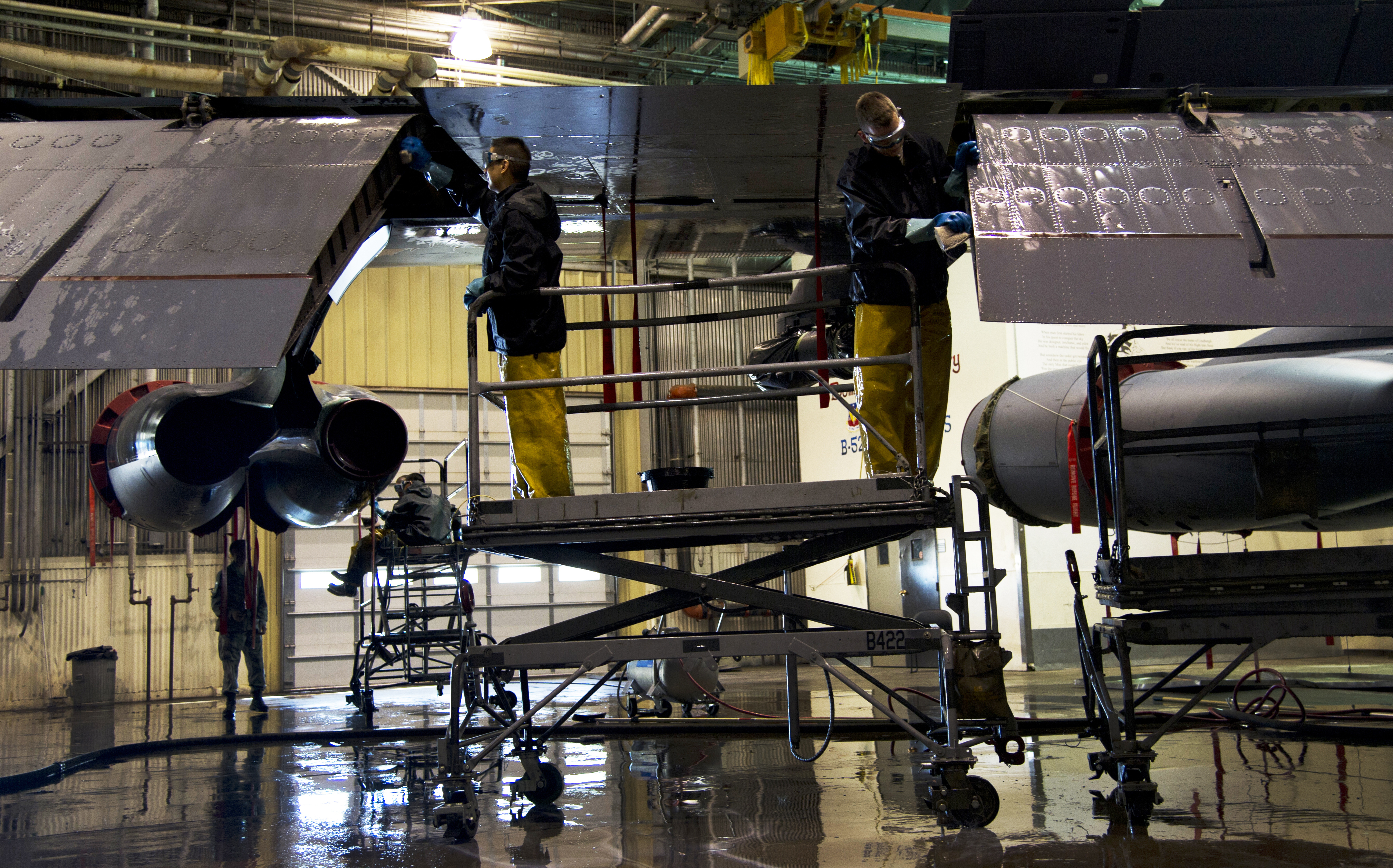

Washing a B-52 isn’t exactly fun, especially with newer troops, who don’t understand that most everything needs to be ‘blended,’ not necessarily cleaned.

B-52s can get very dirty, as you can imagine. A team of four crew chiefs might spend eight or 10 hours cleaning one plane to prevent corrosion. Mainly, you’re getting all the nastiness out of the landing gear, and some of the engine grime off the flaps. There’s a lot of grime, though, and at the end of the wash, it’s inspected by a higher-level supervisor.

Blending just means not making one area super clean — and therefore wasting so much time that the rest of the plane isn’t going to be cleaned — or we’re not going home. To truly and extensively clean the grime off a B-52 would take … forever. Just like many things in the military, the idea is to not stand out. In this instance, that would be a new guy really, intensely cleaning the flaps right behind the engine exhaust, spending an hour making a very small section look very clean. Make everything look nice and even, and go home.

Sucker door screens. This is so minute of a thing, but it really was one of the worst tasks to have to attend to. Here’s a link to what they look like.

Those doors behind the engine’s nose cowling are spring-activated and open on the ground when the engines are run up to allow more air to enter the compressor. Under each door are two holes, allowing the air to enter, maybe an inch and a half in diameter, protected by a small screen to prevent ingestion of debris, secured by two bolts. Lest they become debris elements themselves, each bolt is, of course, safety-wired to the cowling. Two screens per door, 16 doors per cowling, 256 screens to be inspected during every postflight. Relatively easy to inspect, but a huge beast to remove and replace, and then safety-wire them and be sure there’s no debris at all leftover.

I’m sorry to be so pedantic, but some of these things can really illustrate the intense and annoying labor involved.

Urinal stuff! So, there was a “honey pot” on the upper deck near the EWO/Gunner station. Crew chiefs never touched it. If someone in the crew has to poo, they would carry it out. I never experienced it myself, but there was a policy of a crew member being called back out to the aircraft to deal with it if they forgot. The urinal was a different story.

The ‘urinal’ was a five-gallon jerry-can near the main hatch with a large funnel. That’s it. On a post-flight inspection, right after the jet lands, there’d usually be three people, if I remember correctly—one for engine oil, one for body inspection, one for the cockpit. The cockpit person would take the urinal out almost immediately after safeing the ejection seats (which was always the very first thing) because it would already stink. There are stormwater drains all over, and no, urine was not disposed of properly on the flightline.

From Diego Garcia to Afghanistan was about eight hours each way, for about two hours of combat coverage, so 18+ hours total. Many training flights were also long. Lots of urine, but that’s what we signed up for, as airmen. “TYFYS” (thank you for your service) has to encompass all of these weird/bad experiences. I somehow doubt civilians understand what taking orders entails, even on a low level such as this.

For some inspections, the urinal flooring had to be removed and cleaned, and the surrounding under-areas inspected for corrosion. The flooring itself never fit the same way twice, so it was always a terrible job, trying to align as many of the, say, 40 bolts on these weirdly-shaped panels as possible before calling a hopefully sympathetic supervisor over to inspect and sign-off the work as good.

As an aside, crew chiefs working on the flightline were most often pretty far from a bathroom. We did not use the urinal, we used the bomb bay, with the open doors providing ample privacy. If there’s a hydraulic leak, it’s red fluid, so it cannot be mistaken.

As I alluded to earlier, if it’s not red, do not inspect the leak in the bomb bay!

What other stuff just breaks the most? Cowling latches. Lots of stuff didn’t fit right, and we’d be pounding on it to get the job done, but then, of course, it doesn’t fit right in the future either. Not a great position to be in, pounding on the outside of an engine with a rubber mallet.

From a systems standpoint? Tons of small hydraulic leaks. If I were more astute back in the day, I’d have asked the hydraulics or electrics shops, or the ECM (electronic countermeasure) guys, or life support guys, what their nightmares were.

I think lots of times crews during launch would call in for a specialist section for whatever system and a reset circuit breaker would solve the problem. So, I guess, overall, “circuit breakers” would be my mission-critical answer.

The BUFF can carry a lot of very powerful weaponry. This must have been a major consideration on the ground during some operations, right?

In terms of weaponry, yes, it can carry some powerful stuff. Flying from Barksdale, almost all missions are training missions. Ninety-five percent launched without even dummy weapons. Once in a while, you’d have some blue-painted JDAMs or 500-pound non-explosive bombs. Rarely, they’d use live munitions for training over Nevada or wherever. No matter, if weapons (as in the weapons unit) were involved, they would do their work after all maintenance and servicing were done with the aircraft. They’d do their thing, and some of their guys would be around for the launch to talk to the crew, as well.

On Diego Garcia, we were flying combat missions over Afghanistan. Sort of the same situation, though every bomber was taking off with 12 live JDAMs, six on each wing. Three hours of “hover” time after and before eight hours of travel time from and to the “footprint of freedom.” I spent about two months on Diego Garcia, and I can say that the only time I saw a bomber come back with weapons released was this incident.

Nuclear stuff was obviously very different. Every year we had NORIs, and in the lead-up to those exercises, those aircraft participating had to be shit-hot. If your aircraft was participating, you had to have everything possible in working order. It was exciting. Then they loaded the nukes. Eight on a rotary launcher in the bomb bay, six on each wing. If you’re around the aircraft, you can’t be out of sight of anyone else. There’s always a Security Forces cop at the nose of each aircraft posted there. IDs are checked extensively. It’s a serious situation.

It’s also weird to hang out (no general maintenance is going on after the nukes are loaded, but we had to be around in case of anything) around 20 missiles, each of which could take out a whole major city. It’s sobering. It makes one question why and how things operate the way they do. I never felt, in my personal experience, unsafe, but having read about nuclear incidents and knowing how many nukes are out there, it’s really incredible we have made it this far without an accidental nuclear disaster.

B-52s can act as their own cargo haulers to a certain extent. Can you speak to that a bit?

The 47 section in the tail is really the only place to store extra equipment. It has only enough space for a launch kit or two, for ground comms headsets and cords, rags, flashlights, toolboxes, and maybe a couple of drag chutes, assuming there’s a stand at the destination to install it. Also some milk crates of engine oil and hydraulic fluid, of course.

I don’t think I ever saw luggage back there. I’m pretty sure the crew, being deployed, would have their stuff with them in the crew compartment. Again, really it could be used if necessary, like, say going to an overseas airshow without a lot of support equipment or personnel.

You were part of the first deployment of the 11th Bomber Squadron to Guam since the Vietnam War. What was that experience like? Andersen AFB on the island was far less updated than it is now I would imagine? When the 20th Bomb Squadron deployed to Guam, I was just lucky to be asked to volunteer to join them. I got back from leave in February 2003 and saw a note on my dorm room bed (barracks, but it’s the Air Force) from my first sergeant to call as soon as I got in. “Do you want to deploy for eight to 12 months?” Sure, of course. “Alright, pack your bags, you’re going to Guam.”

Great snap decision.

There were a lot of things at play — I’m sure the logistics of moving a squadron of airmen in the early months of 2003 to anywhere but the Middle East was extremely complex — so we didn’t know until basically the day before that we were actually leaving. Hurry up and wait.

We flew Hawaiian Airlines charter from Barksdale to Honolulu, refueled, and went from there to Andersen AFB. The conditions were miserable, but it was interesting because we were the first deployed unit since Vietnam. Housing wasn’t good. 30 people to a bay, working different shifts, sharing a bathroom with five shower stalls. Some people had hotel housing, stacked on each other. But we were on a major base, and outside the base was tourism and culture, which we, as young airmen, took advantage of.

In terms of work, the higher-ups did have to figure out the logistics of how to, you know, actually get bombs and parts and such in a short amount of time. But we were “operational,” meaning deployed aircrews were flying familiarity flights around the Pacific very quickly.

A wild guess is that, since deployed elements have been at Andersen since spring of 2003, it’s probably a lot more habitable now. No idea if they’re using the 30-person bays built during/after World War II. The two-room suites we eventually moved into also sucked, because it’s six people in two rooms, and, again, people working different shifts. The few months I was there, everything was thrown together, as it had to be, even on a major Pacific base, but that was part of the charm.

What do you think of the Air Force’s plan to see these aircraft serve into the back half of the century?

Now the H models are all 60+ years old … and there’s nothing to replace them. The biggest pitfall is that as airframes rack-up cycles, even unpressurized, there’s just stress and corrosion that builds up. At some point it’s not worth it, for any given airframe, to do the extensive maintenance.

As for the new engines, we just saw four-engine concepts that looked pretty ridiculous. … The TF-33s, in my day, were pretty reliable — there weren’t a lot of engine changes — but that’s probably changed in the last 15-plus years. They are probably a ton more maintenance-intensive now.

I wonder about the instrumentation, which I imagine will have to be updated in some way, and integrated into the other systems (hydraulic and electric). I imagine the re-engine process means a lot more data available to everyone involved, which would be great for aircraft longevity and maintenance, but I obviously can’t speak on anything specifically. I just keep wondering what that means for instrumentation and the other systems connected to engine systems. Lower fuel consumption would also mean shorter refuel times and/or higher take-off payloads, which is also good for everyone involved.

Contact the editor: Tyler@thedrive.com