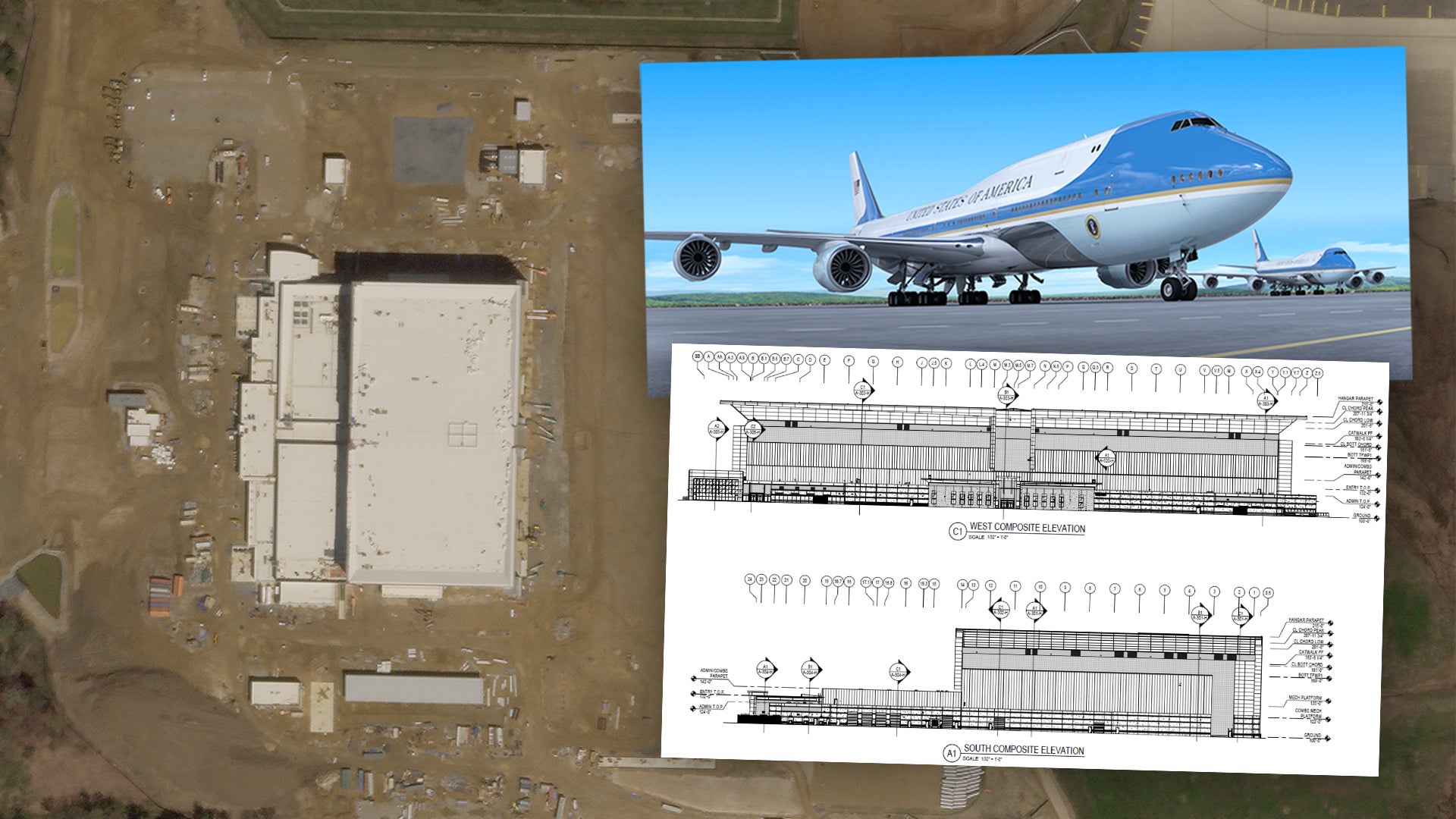

The enormous hangar that will be used to maintain the U.S. Air Force’s two new, sometimes controversial, and staggeringly expensive VC-25B jets that will serve in the Air Force One role is quickly taking shape at Andrews Air Force Base in Maryland. The construction project, which is costing around $250 million, is required since the new jets are marginally bigger than the earlier VC-25A models that are now in use.

Recently obtained detailed satellite imagery, dated April 11, 2021, shows the considerable progress made so far on the huge two-bay hangar, which covers an area of 366,000 square feet, has a length of 660 feet, a width of 575 feet, and a maximum height of 115 feet, according to the Washington Business Journal. When it comes to fitting the VC-25Bs inside, the width of the building is of particular importance, with each of the aircraft having a 225-foot wingspan, larger than the VC-25A, which spans a little under 196 feet.

Official documents have described the new hangar as being designed to “evoke a sense of flight and stateliness through its use of materials, massing and embellishments.” This reflects the fact that this is an environment that’s a far cry from the cluttered halls familiar to most aircraft maintainers.

It’s not just the maintenance hangar itself that’s changing the face of Andrews Air Force Base, which sits just outside Washington, D.C. While work continues on the VC-25Bs in San Antonio, Texas, which are being converted from orphaned 747-8i, an additional 70,000 square feet at Andrews is required for warehouse support areas, while 60,000 square feet is being given over to new administrative buildings. The contract for the hangar was awarded to Clark Construction, headquartered in nearby Bethesda, in late 2018.

Additional infrastructure required to sustain operations by the new Presidential aircraft includes aircraft access taxiways, parking aprons, engine run-up pads, lighting, a refueling system, vehicle parking lot, access roads, perimeter security fencing, and landscaping. As for the aforementioned security fencing, this will be “more decorative in nature than the lower-cost, chain-link fencing normally used for airfield security.” All this is expected to be completed by April next year.

It’s not clear, however, what will happen to the previous hangar used for the VC-25As. This was itself a seriously costly construction project, the custom-built, bunker-like building featuring unique hardening to protect the aircraft. In the accompanying images, the existing VC-25A hangar is the hexagon-shaped building to the north.

Of course, with a project as big and costly as the new Air Force One, it’s not surprising that the aircraft require specialized infrastructure. We have covered the specific details of the forthcoming VC-25Bs before, but it’s worth bearing in mind they are about as far removed from their commercial 747 cousins as it’s possible to get. Among others, they will feature the most advanced defense countermeasures system available, and are protected against electromagnetic pulse caused by detonating nuclear warheads. The aircraft will also be fitted with the most advanced secure airborne communications system of its kind and a bespoke interior with all that’s required for the Commander-In-Chief to go about their work remotely.

All this, plus the infrastructure, including the new hangar, will cost around $5.3 billion. Even taking the VC-25Bs alone, at $4.7 billion they will be the most expensive aircraft ever built. And that’s taking into account the much-publicized claims by former President Donald Trump that he personally slashed the cost of the jets.

As it stands today, the Air Force One recapitalization program is running late, however. According to a recent report from Defense One, delivery of the first VC-25B has been delayed and won’t be handed over by the end of 2024 as planned. A new timeline has not been confirmed.

“We’re going to obviously have to look at the schedule [and] we have to look at it pragmatically,” Lieutenant General Duke Richardson, presently the Military Deputy within the Office of the Assistant Secretary of the Air Force for Acquisition, Technology, and Logistics at the Pentagon, admitted earlier this month.

The reason for this latest holdup is a dispute between manufacturer Boeing and subcontractor GDC Technics, which was selected to install the aircraft’s interiors but ran into delays of around 12 months. The Air Force now expects another firm to pick up responsibility for the interiors, according to Richardson.

Prior to this setback, the program also faced other delays as a result of the COVID-19 pandemic and its effect on the wider supply chain and workforce. As a result, Boeing last month announced a $318 million loss on the VC-25B project. Under the terms of the contract, the manufacturer will cover any cost overruns the program incurs. Of course, questions over costs have been a persistent feature of the program, from the supposed savings of using second-hand aircraft, down to and including the manuals for the aircraft, which alone have a price tag of $84 million.

Exactly when the VC-25Bs arrive at Andrews is, not now at least, unclear. Once they touch down, however, it seems that they will have the high-end hangarage befitting such a prestige — and pricey — program.

Contact the author: thomas@thedrive.com