After nearly a decade of on-again-off-again testing, a one-of-a-kind C-130H Hercules airlifter from the Wyoming Air National Guard is on its way for an evaluation of its latest configuration, which includes upgraded engines and eight-bladed propellers with an advanced electronic control system. Refitting other H-model aircraft with the same modifications could potentially save the U.S. Air Force millions in operating costs, but it’s unclear when this might happen.

On Jan. 6, 2018, the C-130H from the Wyoming Air National Guard’s 153rd Airlift Wing, serial number 92-1536, arrived at the unit’s home at Cheyenne Regional Airport in the state’s capital. The aircraft would receive minor repairs before heading to Eglin Air Force Base in Florida for two years of tests, according a report from the Wyoming Tribute Eagle.

“It’s a culmination of years of effort for the [153rd Airlift Wing] and for the Wyoming Air National Guard,” U.S. Air Force Colonel Paul Lyman, commander of the Wyoming Air National Guard, told the Tribute Eagle. “All we have now is postulated data, but we will see performance [with the modified H model] that is on the par with the J model,” U.S. Air Force Colonel Kevin Campbell, the National Guard director of plans and requirements, added.

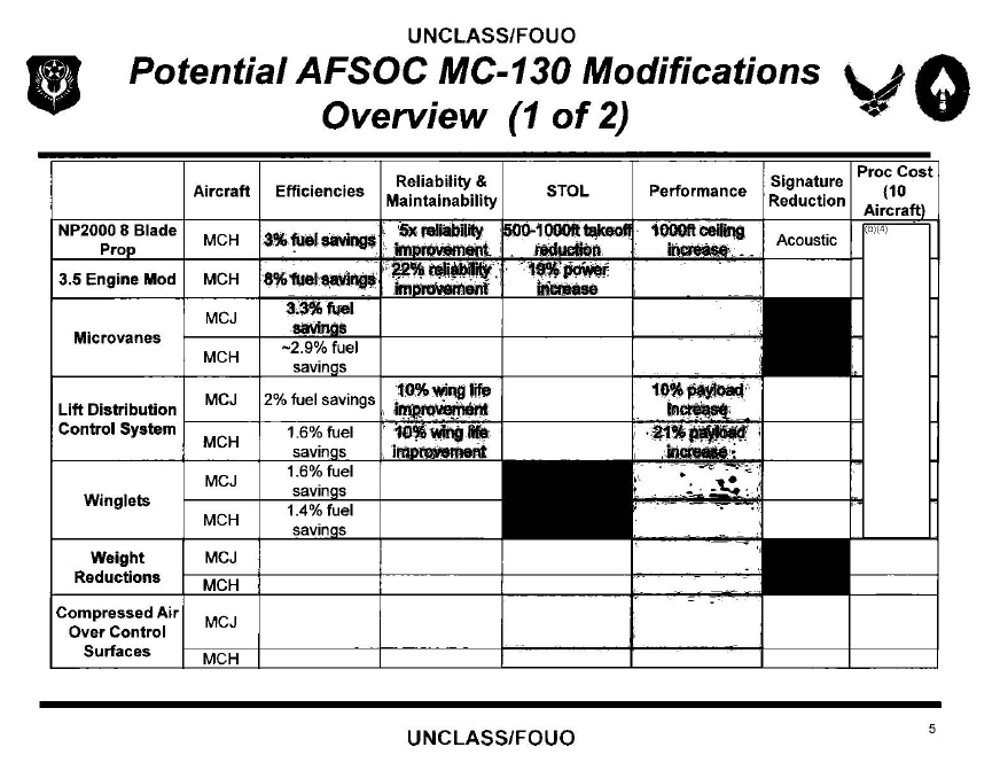

Since 2008, the 92-1536 has served as test bed for a number of proposed modifications to more than 130 other H-series aircraft still in service across the Air National Guard. The aircraft now has three particularly significant sets of improvements.

The most noticeable is the addition of eight-bladed Hamilton Sundstrand NP2000 propellers to each of the four turboprop engines. These are already standard on the U.S. Navy’s E-2 Hawkeye airborne early warning and control aircraft and C-2 Greyhound carrier on-board delivery (COD) planes.

The new propellers vibrate less and make less noise and the aircraft gains increased thrust at equivalent engine torque settings, in turn improving fuel efficiency. A built-in balancing system reduces the need for ground crews to balance the prop manually at regular intervals and fewer vibrations mean less stress on the aircraft as a whole, further reducing the need for maintenance. As an added bonus, the NP2000 is a modular design that takes up less storage space in warehouses or room inside any aircraft, ship, or vehicle delivering spares to established bases or deployed locations.

On top of that, the updated aircraft has an electronic propeller control system, or EPCS, that makes the units more responsive when the crew rapidly advances the throttle. This Air National Guard says this improves the overall reliability of the propellers by approximately 50 percent and removes a safety issue that had contributed to previous mishaps.

The latest addition to 92-1536 is four Rolls-Royce T-56 Series 3.5 turboprop engines that are more fuel efficient and reliable, saving an estimated $250,000 dollars every year on the cost to operate each aircraft, according to the manufacturer’s website.

The U.K.-headquartered engine maker completed flight testing of the uprated design in 2012 and the Air Force certified it in 2015. In addition to being an option for older C-130s, the National Oceanic and Atmospheric Administration has installed the engines on its WP-3D hurricane hunter aircraft.

“We’re confident right now that we’ll see in excess of 12 percent fuel savings and upwards of 25 percent increased time on wing, which will reduce maintenance time,” Colonel Campbell said in 2016. “Those are substantial, and would provide a fairly rapid return on investment. This upgrade would pay for itself; the real question is ‘how fast?’ We’re pretty excited about it and think we’re going to hit it at about the 5 year mark.”

At present, the Air National Guard is hoping to modify 134 more C-130Hs to this standard as part of an upgrade program that will cost approximately $1.3 billion in total. Taken together, though, the modifications could potentially save millions in operating and sustainment costs for the aging airlifters.

But it’s not clear when this project might wrap up, or even really get going. In February 2016, Rolls Royce did deliver the first Series 3.5 engine upgrade kits to the Air National Guard as part of a $36 million dollar contract, but which only covered the aircraft belonging to the 109th and 153rd Airlift Wings.

As already noted, though, the first of these upgrades have been in the works since 2008. At that time, the main focus was updating the capability of the ski-equipped LC-130Hs of the New York Air National Guard’s 109th Airlift Wing, a fleet of unique aircraft that support the U.S. government’s Antarctic research missions.

These aircraft rely on jet-assisted take-off, or JATO, to get off the ice for the return trip. The problem was that the Air Force had a dwindling supply of these rocket motors, which it first bought in the 1950s. The Air National Guard initially considered the NP2000 upgrade by itself as a possible solution, hiring Lockheed Martin to modify a small number of LC-130Hs before shelving the effort.

There was also interest within the Air Force’s special operations community in the NP2000, the EPCS, and 3.5 Series engines, among other upgrades, which could have potentially expanded the capabilities of MC-130H Combat Talon II special operations transport and reduced its auditory signature. The latter point was of particular interest given the aircraft’s mission to insert and extract elite troops from austere locations with limited take-off and landing space within hostile territory.

Though there would be a “high initial cost,” Air Force Special Operations Command estimated adding the NP2000s would have resulted in a three percent fuel saving across MC-130H operations, reduced the aircraft’s take-off run by between 500 to 1000 feet, increased its ceiling by 1,000 feet, and provided a five percent increase in reliability. The 3.5 Series engines could have led to an eight percent fuel savings and a more than 20 percent improvement in aircraft reliability, along with nearly 20 percent more thrust.

Those upgrades did not come to pass, however. In 2015, the Air Force retired the first MC-130H as part of move to ultimately replace the fleet with MC-130Js. That same year, the service retired the AC-130H gunship, as well. The H-based AC-130U and AC-130W remain in service, but the plan is for the new AC-130J to eventually supplant at least the U models.

In August 2017, Inside Defense reported that the New York Air National Guard was in talks with Lockheed Martin about a potential LC-130J model to outright replace its older aircraft. All of this reflects a steadily, if slowly shrinking C-130H fleet across both the active Air Force and its reserve components, all of which could reduce the impetus to pursue the upgrade project.

As of 2014, the Air National Guard had a requirement to upgrade 154 H-models. The next year, this number had dropped to 135. By 2020, when the tests of the latest iteration of the Wyoming Air National Guard’s prototype upgraded C-130H finish up, the total fleet may have shrunk even more. The last active duty H-model headed to the Bone Yard in October 2017.

In addition, the C-130Hs, which first entered service in 1974, are running up against separate airworthiness issues as the aircraft’s center wing box ages out. Between 2007 and 2013, Lockheed Martin received a more than $650 million contract to replace these sections on more than 100 H-model aircraft, but not nearly the entire fleet across the active and reserve components. The plan also involved slowing the C-130J production by taking newly made wing boxes off that assembly line and installing them in older aircraft.

Though the engine and propeller upgrades could expand their capability, the remaining C-130Hs might still need a another service life extension program in order to keep flying long enough for the cost savings to materialize. As of 2007, adding a new wing box cost to just one of the older aircraft an estimated $6.5 million.

At the same time, Lockheed Martin is continuing produce the more advanced C-130J, as well as LM-100Js for the civilian commercial market. As time goes on, and unit prices drop, the Air Force may decide it is simpler and not significantly more expensive to just replace the older C-130Hs. The cost factor may be increasingly less an issue overall if President Donald Trump and his administration can follow through on their plans to dramatically expand the United States’ defense budget.

All told, by the time the 153rd’s C-130H returns from Florida, at which point this modernization effort will have effectively been going on for more than a decade, the Air National Guard’s understanding of its future needs, and its available options, may have change significantly.

Contact the author: joe@thedrive.com